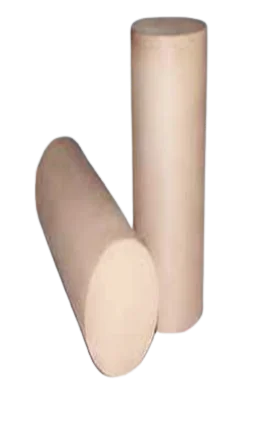

Polyglycolic Acid Rod for Oilfield Applications: Enhancing Efficiency and Performance

In the demanding world of oilfield operations, the need for high-performance materials that can withstand extreme conditions is critical. From the high pressures of deep wells to the corrosive environments of offshore fields, the oil and gas industry requires solutions that are both efficient and durable. One such breakthrough material that has been gaining significant attention in recent years is the polyglycolic acid rod for oilfield applications. Offering a unique set of properties, these rods are transforming how operators approach challenges in drilling, production, and well intervention. This article East explores the key benefits and applications of polyglycolic acid rods for oilfields, focusing on how they contribute to the optimization of oilfield operations.

Key Properties of Polyglycolic Acid Rod for Oilfield Operations

The polyglycolic acid rod for oilfield offers several distinctive properties that make it a superior choice for various operations. Understanding these properties is essential for oilfield operators when determining whether PGA rods are the right fit for their specific applications. Below are the key attributes that set polyglycolic acid rods apart:

-

Biodegradability: One of the standout features of the polyglycolic acid rod for oilfield applications is its biodegradable nature. This makes it an environmentally friendly choice for operations in sensitive environments, such as offshore drilling sites or environmentally regulated fields. Over time, the PGA material naturally degrades under the influence of moisture, heat, and other environmental factors, reducing the need for labor-intensive retrieval operations. This characteristic also minimizes waste management challenges, making it easier to maintain environmentally responsible practices.

-

High Strength-to-Weight Ratio: The polyglycolic acid rod for oilfield offers a high strength-to-weight ratio, which is crucial for many oilfield operations. This means that the rods can withstand high mechanical forces without being overly bulky or heavy. The lightweight nature of PGA rods also enhances the efficiency of handling and deployment, reducing wear and tear on equipment and allowing for more cost-effective transportation.

-

Chemical and Corrosion Resistance: Oilfields are notorious for their harsh conditions, including exposure to corrosive elements such as hydrogen sulfide, carbon dioxide, and various acids. The polyglycolic acid rod for oilfield is highly resistant to corrosion, making it a reliable choice for long-term use in these environments. Its chemical resistance ensures that it maintains structural integrity, even when exposed to aggressive fluids and gases commonly found in the oil and gas industry.

-

Thermal Stability: PGA rods maintain their performance in high-temperature environments. The polyglycolic acid rod for oilfield can withstand elevated temperatures that are often encountered in deep well operations, ensuring that the rod retains its mechanical strength and functionality, even in extreme heat. This thermal stability makes PGA rods a suitable choice for deep well interventions and operations where traditional materials may fail due to temperature fluctuations.

-

Controlled Degradation: Unlike traditional materials, which may need to be manually extracted and disposed of at the end of their service life, polyglycolic acid rods for oilfield applications are designed to degrade over time in a controlled manner. This makes them particularly useful in applications where permanent installation is not required, such as temporary well plugs or other short-term interventions. The controlled degradation process ensures that the rods break down in a predictable manner, without causing damage to the surrounding environment or infrastructure.

Applications of Polyglycolic Acid Rod for Oilfield Operations

The polyglycolic acid rod for oilfield has found a wide range of applications within the industry, offering solutions to common challenges faced during drilling, well intervention, and production. Here are several key areas where PGA rods have been successfully implemented:

-

Well Intervention: In oilfield operations, well intervention is essential to maintaining and enhancing well productivity. Polyglycolic acid rods are used in temporary applications where their biodegradability allows for easy removal without the need for complex extraction procedures. These rods are used to create plugs in the wellbore, seal off unwanted zones, or temporarily isolate sections of the well to carry out other operations. Once the job is completed, the rods break down over time, eliminating the need for retrieval.

-

Temporary Well Plugs: Temporary well plugs are essential in a variety of oilfield operations, including zonal isolation, temporary abandonment, or well testing. The polyglycolic acid rod for oilfield is an ideal material for these applications due to its controlled degradation properties. These rods can be installed in the wellbore to form a reliable temporary barrier and will degrade at a predetermined rate after use, leaving no long-term waste behind. This eliminates the need for complex retrieval and disposal procedures.

-

Casing and Liner Systems: In many oilfields, casing and liner systems are crucial to prevent wellbore collapse and to manage the flow of fluids. The polyglycolic acid rod for oilfield can be integrated into these systems to provide enhanced mechanical support while maintaining flexibility. These rods help ensure the structural integrity of the wellbore, even in harsh conditions, and their corrosion-resistant properties ensure that they remain functional over time, even when exposed to aggressive fluids and gases.

-

Downhole Tools and Equipment: The use of downhole tools and equipment, such as drilling and completion tools, is a critical aspect of any oilfield operation. Polyglycolic acid rods are utilized in various downhole tools to enhance their strength, flexibility, and resistance to corrosion. These rods provide reliable support and durability, ensuring that the tools can withstand the high pressures and temperatures often encountered in deep well operations. Moreover, their biodegradability makes them a more sustainable option for tools that are used temporarily.

-

Hydraulic Fracturing: In hydraulic fracturing, or fracking, operations, temporary plugs are often used to isolate certain sections of the well for treatment. The polyglycolic acid rod for oilfield serves as an excellent choice for these temporary plugs. After the fracturing process is completed, the PGA rods naturally degrade over time, allowing for efficient wellbore cleanup and eliminating the need for costly and labor-intensive retrieval processes.

The polyglycolic acid rod for oilfield represents a significant advancement in oilfield operations, offering a combination of strength, biodegradability, and chemical resistance that traditional materials simply cannot match. By providing a reliable, environmentally friendly solution for a wide range of applications, these rods are helping oil and gas operators achieve greater operational efficiency, cost savings, and sustainability. Whether used in well interventions, casing systems, or hydraulic fracturing, the unique properties of polyglycolic acid rods are revolutionizing how oilfields are managed, setting the stage for more efficient and eco-friendly operations in the future.

https://www.eastnewmaterial.com/PGA-rod.html

www.eastnewmaterial.com

Chengdu East New Material Co.,Ltd.