Aluminum Extrusion Machining: A Key to Sustainable Green Energy Industry

The green energy industry, driven by the need to reduce carbon emissions and promote sustainable energy solutions, is increasingly dependent on advanced manufacturing techniques. Among these, aluminum extrusion machining plays a pivotal role in producing high-performance components for renewable energy technologies. From solar panels to wind turbines, aluminum extrusion machining ensures that key components are manufactured with high precision, durability, and lightweight properties. This article Full-Linking explores how aluminum extrusion machining supports the green energy sector, enhancing the efficiency and sustainability of renewable energy systems.

What is the Aluminum Extrusion Machining?

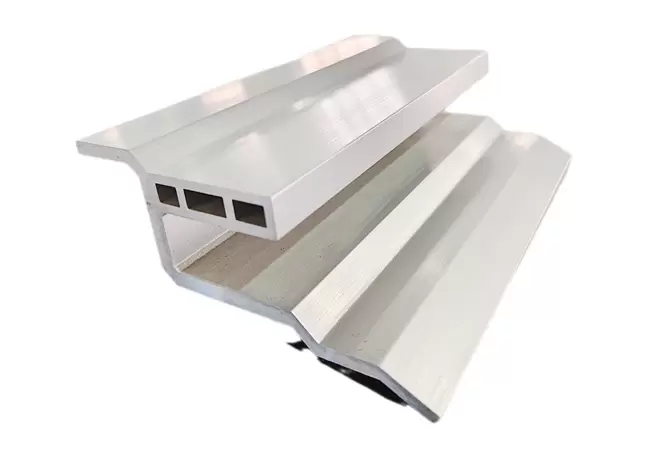

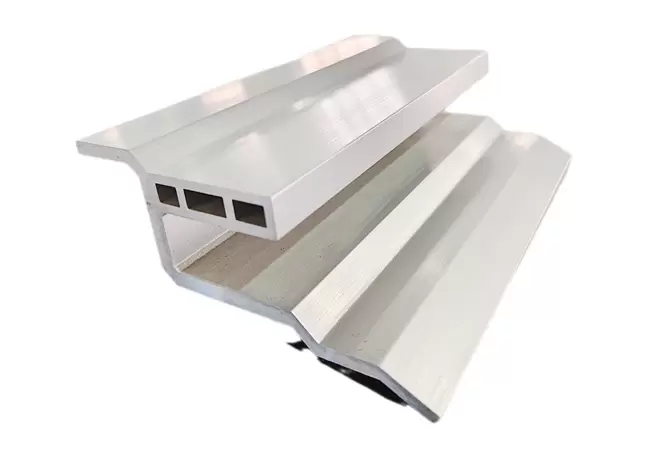

Aluminum extrusion machining refers to a manufacturing process where aluminum billets (solid blocks of aluminum) are heated and then forced through a die to create a continuous profile with a fixed cross-sectional shape. The extruded aluminum can then be further processed using machining techniques such as cutting, drilling, and milling to meet specific design requirements. The process of aluminum extrusion offers several advantages for the green energy industry, including the production of lightweight yet strong components, ease of shaping for complex geometries, and high efficiency in terms of material utilization. Aluminum, due to its excellent corrosion resistance, thermal conductivity, and recyclability, is a preferred material for many applications in the green energy sector.

Key Benefits of Aluminum Extrusion Machining in Green Energy

The green energy industry benefits from aluminum extrusion machining in multiple ways, ranging from material efficiency to design flexibility. Some of the primary advantages include:

1. Lightweight and Strong Components

One of the most significant benefits of aluminum extrusion machining is the creation of lightweight components with high strength-to-weight ratios. This property is particularly valuable in industries like wind and solar power, where reducing the weight of key components, such as structural frames and support systems, is essential for improving performance and reducing transportation costs. For instance, in wind turbine manufacturing, the use of lightweight aluminum extrusions for tower support structures and rotor blades can help improve the overall efficiency of the turbine by reducing the amount of energy required to transport and assemble the components. The strength of aluminum, combined with its lightweight nature, allows for the production of robust, durable components without compromising the overall performance of the system.

2. Corrosion Resistance and Durability

Aluminum's inherent corrosion resistance is a critical factor in the green energy industry, particularly for components exposed to harsh outdoor environments. Solar panels, wind turbines, and other renewable energy systems often operate in challenging conditions, from high humidity and saltwater exposure to extreme temperatures. Aluminum extrusion machining creates components that maintain their integrity over long periods, even under these harsh conditions. Aluminum extrusions used in solar panel frames, for example, are highly resistant to corrosion, which helps extend the lifespan of the entire solar system. This durability is essential for reducing maintenance costs and ensuring that green energy systems can provide reliable, long-term performance with minimal intervention.

3. Recyclability and Sustainability

One of the defining features of aluminum is its recyclability. Aluminum can be recycled indefinitely without losing its properties, making it a perfect fit for the sustainability goals of the green energy industry. Aluminum extrusion machining allows manufacturers to work with recycled aluminum, reducing the carbon footprint associated with raw material extraction and processing. The use of recycled aluminum in the production of green energy components not only supports sustainability but also helps reduce the overall cost of manufacturing. In solar energy systems, for example, using recycled aluminum for the frame construction reduces the demand for new raw materials and decreases energy consumption, further enhancing the environmental benefits of solar energy.

4. Design Flexibility and Precision

Aluminum extrusion machining allows for the creation of highly complex shapes and profiles, which are often required in the green energy industry. The versatility of the extrusion process means that manufacturers can produce components with unique cross-sectional shapes tailored to specific requirements. In wind and solar applications, where precise measurements and customized designs are crucial, aluminum extrusion machining offers the flexibility needed to meet these demands. For instance, in solar panel systems, the ability to create extrusions that are tailored to the specific size and shape of the panel frame ensures that the components are optimized for both strength and weight, facilitating easier assembly and improving the overall efficiency of the system. The precision offered by aluminum extrusion machining also ensures that parts are made to exact tolerances, enhancing the performance of renewable energy systems.

Aluminum extrusion machining is a cornerstone of the green energy industry, providing lightweight, durable, and environmentally friendly components for renewable energy technologies. From solar power systems to wind turbines and hydropower plants, aluminum extrusions offer the strength, corrosion resistance, and recyclability needed to enhance the efficiency and sustainability of green energy systems. The combination of material efficiency, precision, and design flexibility makes aluminum extrusion machining an essential process for meeting the growing demand for renewable energy solutions. As the green energy sector continues to evolve, aluminum extrusion machining will remain at the forefront, helping to drive innovation, reduce environmental impact, and support the global transition to a more sustainable energy future.

https://www.fulllinking.com/aluminum-extrusion-service.html

www.fulllinking.com

Full-Linking