What should we pay attention to when transporting and storing tungsten carbide circular saw blades?

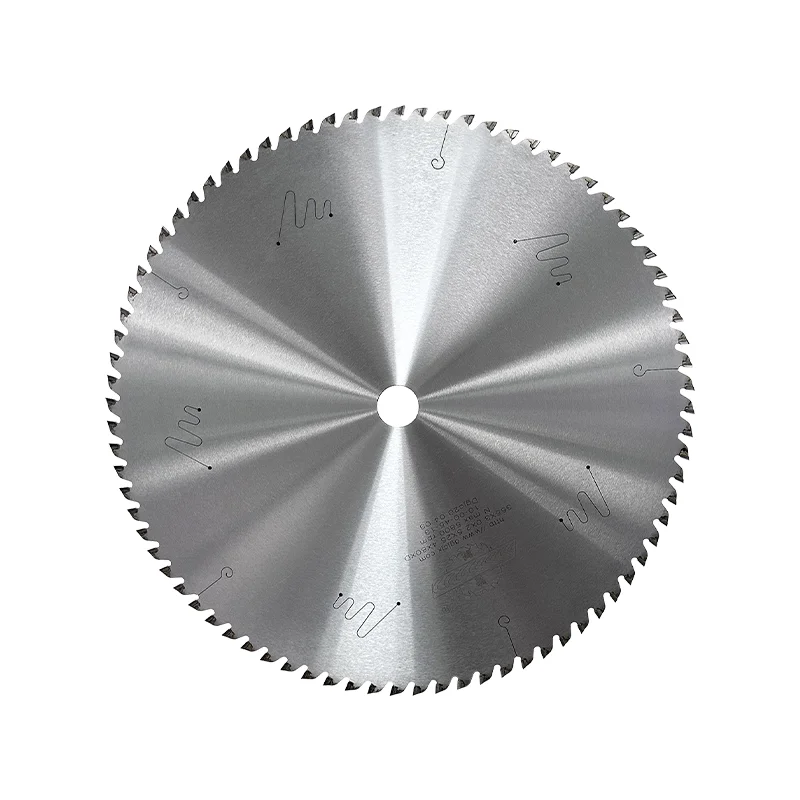

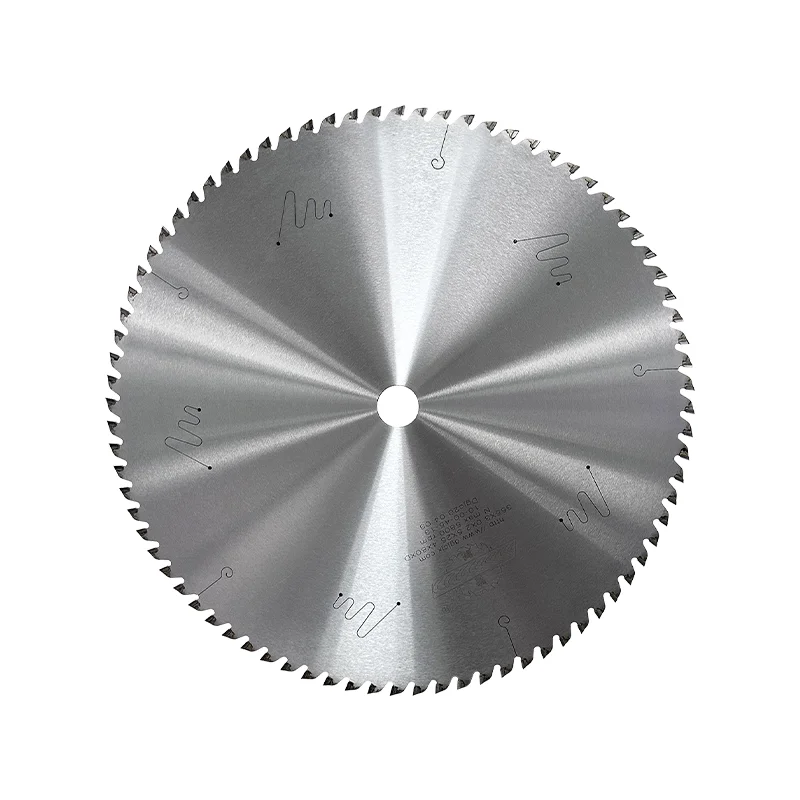

As a high-precision and high-strength cutting tool, tungsten carbide circular saw blades are widely used in metal processing, wood cutting, aluminum profile cutting and precision processing of various hard materials. It has high hardness, strong wear resistance and high cutting efficiency, but at the same time, tungsten carbide circular saw blades are also very brittle, especially at the edge teeth. If they are not properly protected during transportation and storage, they are prone to tooth collapse, tooth loss, deformation and other problems, which directly affect the use effect and even cause economic losses. Therefore, understanding and mastering the precautions for tungsten carbide circular saw blades during transportation and storage is of great significance to extending the life of the saw blades and ensuring the cutting quality. This article will deeply analyze the key points of transportation and storage of tungsten carbide circular saw blades from multiple angles to help users effectively avoid common problems in actual operation.

1. Precautions for transportation of tungsten carbide circular saw blades

1.1 Use special packaging to prevent sawtooth collision The biggest weakness of tungsten carbide circular saw blades is their sharp and fragile teeth. During transportation, a special packaging box equipped by the original factory or customized should be used, which is generally a plastic card slot structure or a foam wrapping structure, which can effectively fix the saw blade to prevent movement and bumps. If you need to transport multiple saw blades at the same time, make sure there are independent spacers between each blade, such as cardboard or foam gaskets, to prevent the teeth from colliding with each other.

1.2 Place vertically to avoid heavy pressure on flat stacks

Circular saw blades should not be stacked horizontally during transportation, otherwise the weight will be concentrated on the bottom saw blade, which may easily cause deformation of the center hole or stress cracking of the teeth. It is recommended to use vertical card placement, especially for large saw blades (over 300mm in outer diameter). At the same time, there should be a certain buffer structure inside the packaging box to avoid internal friction caused by shaking during transportation.

1.3 Moisture-proof and rust-proof packaging

Although tungsten steel itself is not easy to rust, the main material of many tungsten carbide circular saw blades is alloy steel, and there may be an anti-rust coating on its surface. Once damp, it is easy to oxidize and rust. Therefore, it is recommended to add desiccant or use vacuum packaging when packaging, especially in long-distance transportation or storage in a humid and hot environment.

1.4 Clear labeling and manual matching

To ensure correct operation during transportation, the outside of the package should be affixed with fragile labels, up and down direction marks and product specification labels. For mixed transportation of multiple specifications, clear labels can prevent misuse during unpacking. At the same time, it is best to attach an operating manual or user guide to facilitate customers to understand the unpacking, installation, operation and maintenance methods.

2. Precautions for storage of tungsten carbide circular saw blades

2.1 Storage environment: dry, ventilated, anti-corrosion

Saw blades should be stored in a dry, ventilated, and moderately warm environment, avoiding warehouses with high humidity or corrosive gases. For example, chemical warehouses with acidic or alkaline volatiles are not suitable for the storage of metal tools. Water vapor, dust and oil in the air may cause damage to the surface of the saw blade or even rust on the teeth.

2.2 Storage method: vertical placement is better than horizontal placement

Tungsten carbide circular saw blades are also recommended to be placed vertically in a dedicated saw blade rack when stored to avoid stress concentration due to their own weight, resulting in deformation of the center hole or the whole. If conditions limit the need to lay flat, no more than 3 to 5 pieces should be placed, and soft spacers should be placed between each piece to prevent friction and damage.

2.3 Regular inspection to prevent aging loss

Tungsten carbide circular saw blades that have been stored for a long time should be inspected every 3-6 months to observe whether they have oxidation, saw tooth damage, corrosion and other problems. Especially for saw blades in batch inventory, they should be re-inspected before delivery or use to ensure product quality. At the same time, avoid mixing with other heavy metal tools to prevent accidental bumps and damage.

2.4 Classification and filing for easy management and deployment

Tungsten carbide circular saw blades come in many types, such as different outer diameters, different numbers of teeth, different tooth shapes, and different uses (such as cutting aluminum, cutting steel, cutting wood, etc.). If they are stored in a disorderly manner, it is not only not conducive to management, but also easy to make mistakes. It is recommended to store them according to specifications and models, and at the same time establish electronic ledgers or label files to improve warehousing efficiency and delivery accuracy.

3. Suggestions for handling special situations

3.1 Reprocessing or handling when the inventory cycle is too long

If some tungsten carbide circular saw blades are unsalable for a long time due to unpopular specifications or excessive purchases, it is recommended to entrust a professional organization to re-grind or coat them after a certain period of time to restore the sharpness of the blade and improve the cost-effectiveness of subsequent use.

3.2 Avoid direct sunlight and high-temperature environments

Although tungsten steel has good high-temperature resistance, long-term direct sunlight or exposure to high-temperature environment may cause oxidation of the coating and annealing of the material, affecting the service life. Therefore, warehouses should avoid storage near windows, under roof,s and near heat sources in direct sunlight.

Although tungsten carbide circular saw blades are a high-hardness, high-performance cutting tool, its high brittleness also determines its sensitivity to transportation and storage conditions. Whether it is manufacturer delivery, dealer turnover, or end-user warehouse storage, as long as there is a slight negligence in these seemingly "non-use links", it may cause unnecessary damage and economic losses.

Therefore, it is recommended that all practitioners related to tungsten carbide circular saw blades should adhere to the principle of "fine management" in the transportation and storage links, establish standard operating procedures (SOP), and regularly train employees' operating skills and safety awareness. Only in this way can the high-efficiency performance of tungsten carbide circular saw blades be truly brought into play, the service life can be extended, and production efficiency can be improved. If you are a purchaser, distributor or end user of tungsten carbide circular saw blades, if you encounter problems during use, selection or maintenance, please feel free to contact us - we are a professional tungsten carbide circular saw blade company, providing one-stop solutions to help your cutting process be more stable and efficient!

www.chinechernmachine.com

chinechernmachine