What Are Extruder Feeding Devices and Why Are They Essential in Modern Manufacturing?

In modern manufacturing, especially within the plastics industry, precision, efficiency, and consistency are critical to success. One component that plays a vital role in achieving these goals is the extruder feeding device. Although it may seem like a minor part of an extrusion system, the feeding device has a direct impact on product quality, throughput, and material usage.

This article explores what extruder feeding devices are, how they work, and why they are essential in today’s advanced manufacturing environments—particularly in plastic processing lines engineered by experts like JiaXin Mechanical Manufacture.

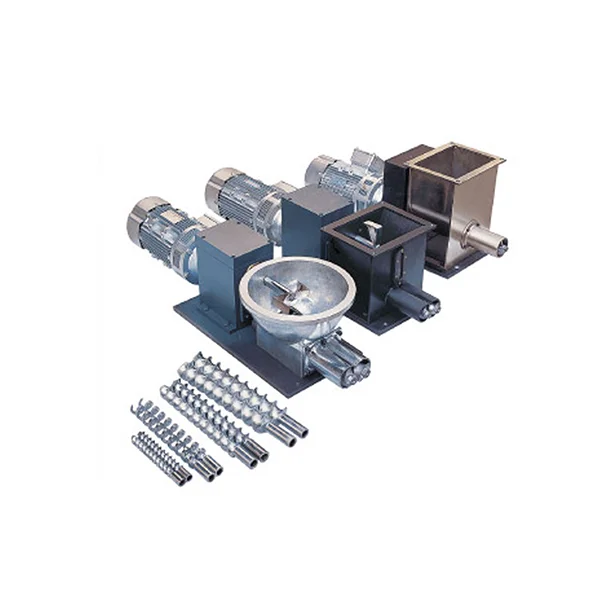

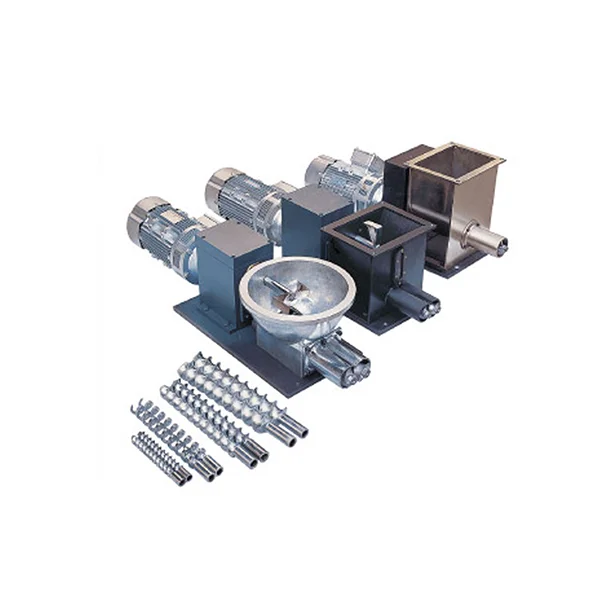

What Are Extruder Feeding Devices?

An extruder feeding device is the component responsible for delivering raw materials—usually in pellet, powder, or flake form—into the extruder's screw system. The consistency and accuracy of this material delivery affect the performance of the entire extrusion process.

Feeding devices are typically categorized into two main types:

-

Volumetric Feeders: These feed a constant volume of material over time, often used in applications where precise mass control is not critical.

-

Gravimetric Feeders: These use weight-based control to deliver material, ensuring precise dosing and consistent quality, especially for multi-component or color-sensitive products.

Why Are Feeding Devices So Important?

1. Consistency in Material Flow

Feeding devices ensure that the extrusion screw receives a steady, uninterrupted flow of material. This consistency is crucial for maintaining product dimensions, texture, and strength—especially in applications like sheet production or composite materials.

2. Increased Efficiency and Output

An optimized feeding system minimizes downtime and maximizes the extruder’s output capacity. JiaXin Mechanical Manufacture integrates advanced feeding solutions into its high-efficiency twin-screw and single-screw extruders, helping customers achieve higher throughput with lower energy consumption.

3. Reduced Waste and Cost Savings

Accurate feeding reduces the likelihood of overfeeding or underfeeding, which can lead to material waste, uneven extrusion, or machine wear. Gravimetric systems are particularly beneficial in PET recycling or compounding lines, where raw material costs are high and quality control is strict.

4. Flexibility for Different Materials

Modern feeding systems are designed to handle a wide range of materials, from virgin resin pellets to recycled flakes and fillers. JiaXin’s complete extrusion lines—such as sheet production lines and PET recycling systems—often include custom feeding solutions that adapt to different material characteristics, including bulk density, moisture content, and flow behavior.

5. Automation and Smart Control Integration

In today’s smart factories, extruder feeding devices can be integrated with PLC and SCADA systems for real-time monitoring and automated adjustments. JiaXin offers turnkey engineering solutions with full system integration, helping manufacturers embrace Industry 4.0 with minimal complexity.

JiaXin Mechanical Manufacture: Your Expert in Extrusion Technology

With years of experience in the design and manufacturing of plastic extrusion and forming machinery, JiaXin Mechanical Manufacture has established itself as a trusted provider of advanced extrusion systems. The company specializes in:

-

Twin-screw extruders

-

Single-screw extruders

-

Sheet production lines

-

PET recycling lines

-

Customized compounding and material recovery systems

By incorporating high-precision extruder feeding devices into every system, JiaXin ensures reliable material flow, superior product consistency, and long-term performance across a wide range of applications.

Conclusion

Extruder feeding devices may not be the most visible component on your production floor, but their impact on efficiency, quality, and cost control is undeniable. As manufacturing demands grow more complex, choosing the right feeding technology—and working with a proven equipment supplier like JiaXin Mechanical Manufacture—can provide a clear competitive edge.

Whether you are building a new extrusion line or upgrading your current setup, investing in the right feeding system is a smart move toward more efficient, sustainable, and high-performance production.

www.tcextruder.com

JiaXin Mechanical Manufacture CO., Ltd