Unveiling the Core Distinctions: Mechanical Fuel Pump vs. Electric Fuel Pump

In the realm of automotive engineering, fuel delivery systems play a pivotal role in ensuring the efficient and reliable operation of vehicles. Two prominent types of fuel pumps, mechanical and electric, have emerged as the primary contenders in this domain. While both serve the purpose of delivering fuel to the engine, they possess distinct characteristics that set them apart. In this article, we will delve into the intricacies of these fuel pumps, exploring their differences, advantages, and applications.

- Operating Principle:

The fundamental disparity between a mechanical fuel pump and an electric fuel pump lies in their operating principles. A mechanical fuel pump relies on the reciprocating motion of a lever or diaphragm, driven by the engine's camshaft or crankshaft, to draw fuel from the tank and deliver it to the carburetor or fuel injection system. On the other hand, an electric fuel pump utilizes an electric motor to generate the necessary pressure for fuel delivery. - Fuel Pressure and Flow Rate:

One of the key distinctions between these two fuel pumps is the pressure and flow rate they can achieve. Mechanical fuel pumps typically operate at lower pressures, ranging from 4 to 10 psi (pounds per square inch), and have a moderate flow rate. In contrast, electric fuel pumps can generate higher pressures, often exceeding 40 psi, and offer a higher flow rate, ensuring a consistent supply of fuel to meet the engine's demands. - Reliability and Durability:

When it comes to reliability and durability, electric fuel pumps have the upper hand. Mechanical fuel pumps, being mechanically driven, are prone to wear and tear over time, especially in high-performance applications. Electric fuel pumps, on the other hand, have fewer moving parts, resulting in reduced mechanical failures. Additionally, electric fuel pumps are less susceptible to vapor lock, a phenomenon that can occur in mechanical fuel pumps under high-temperature conditions. - Installation Flexibility:

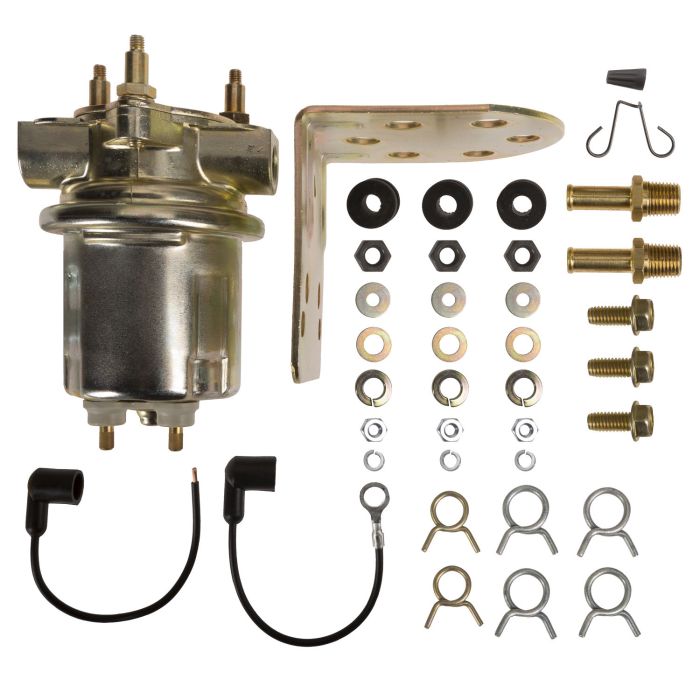

Electric fuel pumps provide greater flexibility in terms of installation options. They can be mounted anywhere in the fuel line, including inside the fuel tank, due to their self-priming capability. This versatility allows for more efficient fuel delivery and simplifies the overall design of the fuel system. In contrast, mechanical fuel pumps are typically mounted on the engine block and require a direct mechanical connection to the camshaft or crankshaft. - Applications:

The choice between a mechanical fuel pump and an electric fuel pump depends on the specific requirements of the vehicle and its intended use. Mechanical fuel pumps are commonly found in older vehicles, particularly those equipped with carburetors. They are also prevalent in certain classic and vintage car models. Electric fuel pumps, on the other hand, are widely used in modern fuel injection systems, as well as high-performance and turbocharged engines that demand higher fuel pressures.

Conclusion:

In conclusion, the biggest difference between a mechanical fuel pump and an electric fuel pump lies in their operating principles, fuel pressure and flow rate capabilities, reliability and durability, installation flexibility, and applications. While mechanical fuel pumps have their historical significance and are still relevant in certain contexts, electric fuel pumps have emerged as the preferred choice for modern vehicles, offering improved performance, reliability, and adaptability to various fuel system designs.