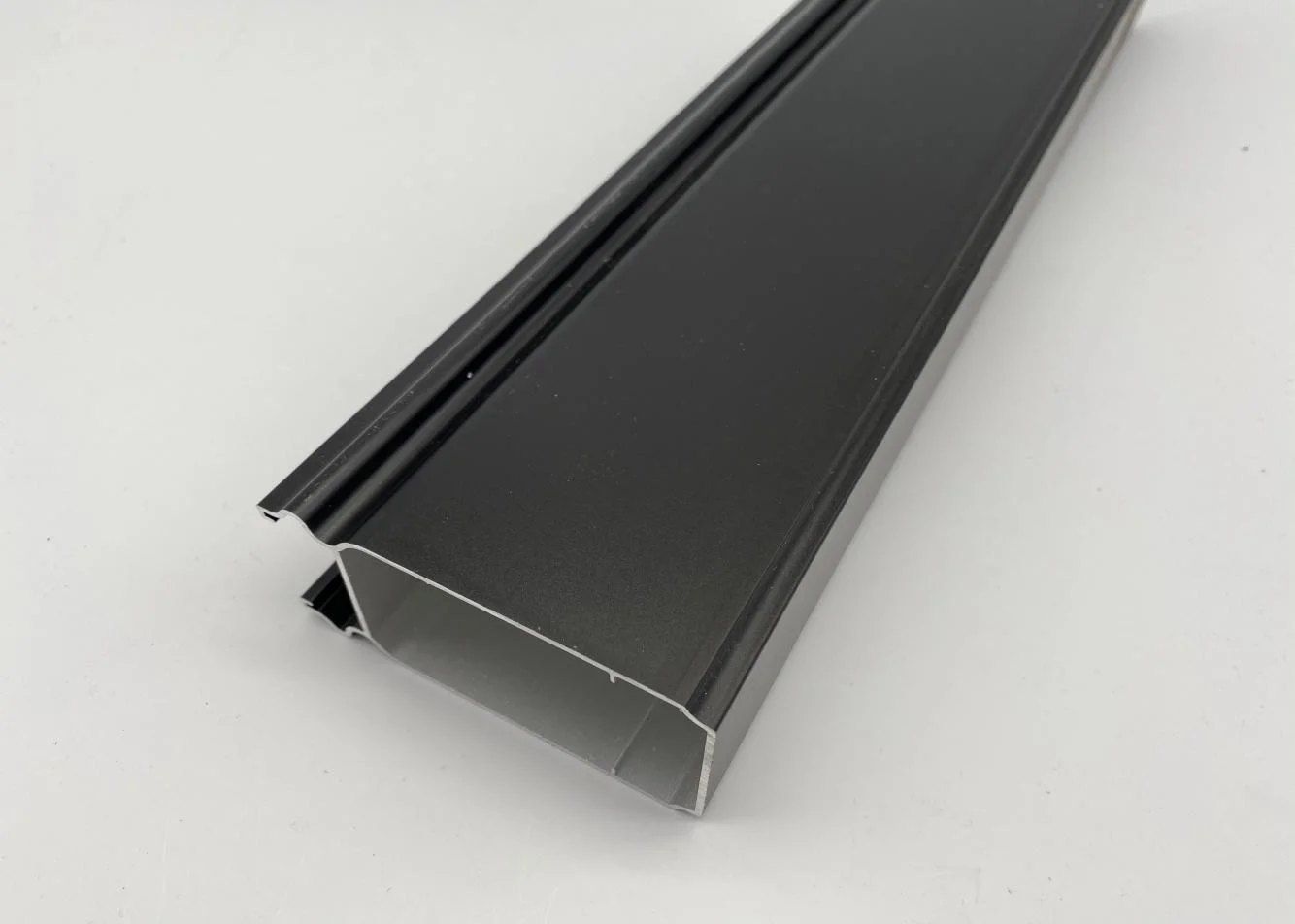

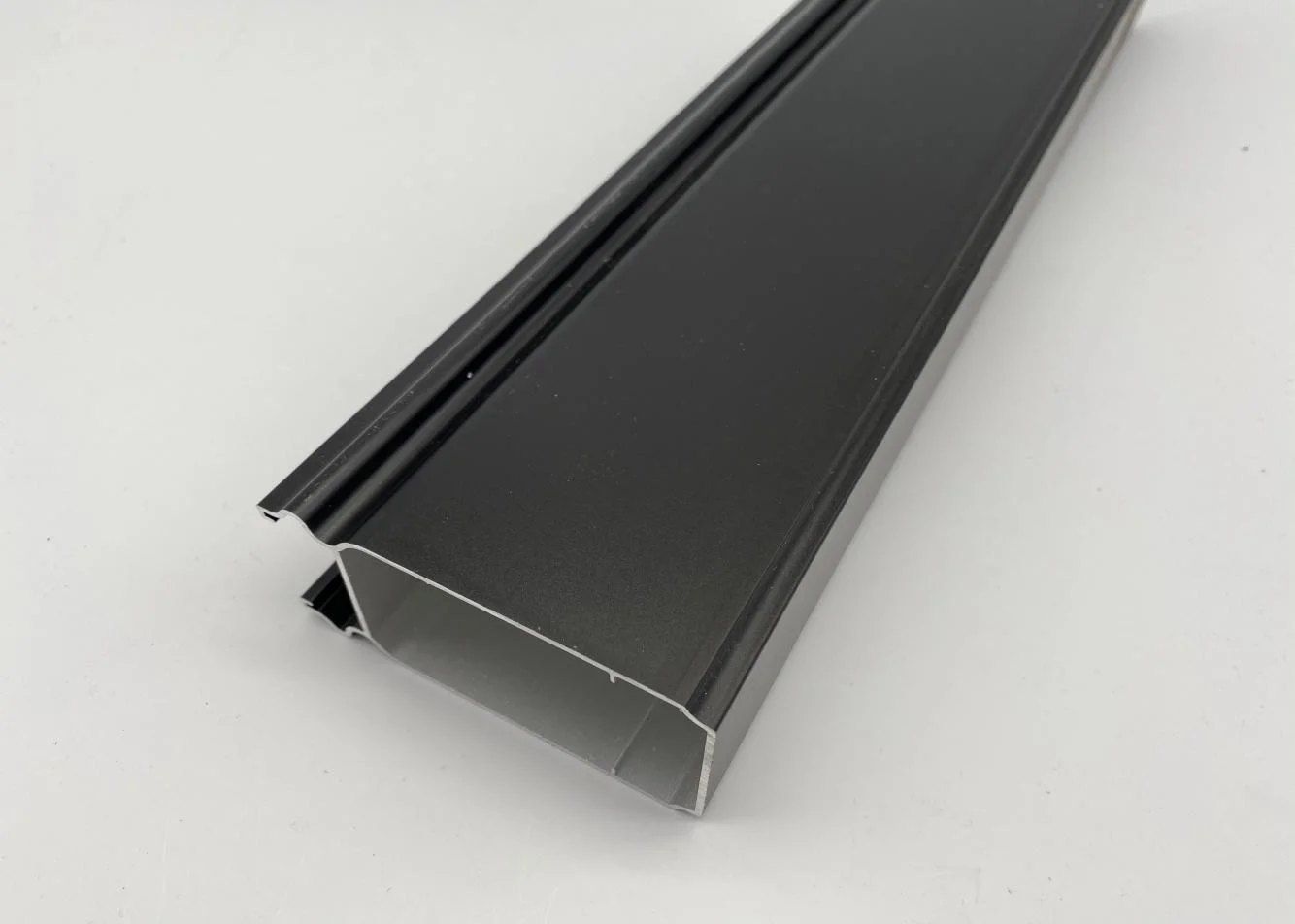

The Ultimate Guide to Electrolytic Coated Aluminium Profiles: Features, Grades, and Applications

When it comes to choosing reliable, durable, and visually appealing materials for architectural and industrial projects, Electrolytic Coated Aluminium Profiles stand out as a top-performing solution. Combining advanced surface treatment with excellent corrosion resistance, these profiles are ideal for long-term use in even the harshest environments.

In this guide, we will walk you through the key features, coating grades, and practical applications of electrolytic coated aluminium profiles—based on real industry standards and advanced manufacturing practices, like those employed at Jiangxi KaiMeiDa Aluminum, a leading aluminium profile manufacturer in China.

1. What Are Electrolytic Coated Aluminium Profiles?

Electrolytic coated aluminium profiles are aluminium alloy extrusions that undergo a multi-layer surface treatment, combining anodic oxidation, electrophoretic coating, or powder coating to create a protective and decorative finish.

At Jiangxi KaiMeiDa, we use high-grade industrial aluminium (YS67-93) and apply coatings in compliance with national standard GB5237.3-2008, ensuring consistent quality and long-term performance. These profiles are suitable for doors, windows, curtain walls, office partitions, and various industrial frameworks.

2. Key Features That Set Them Apart

Electrolytic coated aluminium profiles offer a wide range of performance advantages that exceed traditional metals or untreated aluminium:

-

Corrosion Resistance: The composite coating layer effectively blocks erosion from acids, alkalis, and salt spray, achieving a corrosion resistance level of ≥9.5 grade.

-

Excellent Adhesion: Coating adhesion is rated at 0 grade, which is the highest level, preventing peeling or flaking under extreme conditions.

-

High Hardness: Surface hardness reaches ≥3H, making the profile resistant to scratches and surface damage.

-

Smooth Surface Finish: The texture is refined and consistent, offering a clean, modern appearance.

-

Multiple Finishes: Available in silver white, champagne, bronze, and sand-textured matte—ideal for aesthetic flexibility in design.

3. Understanding Coating Grades: Grade A vs. Grade B

Coating thickness and quality vary depending on performance requirements. At KaiMeiDa, we offer two standardized coating grades:

-

Grade A:

-

Oxide Layer: ≥10μm

-

Paint Film: ≥12μm

-

Total Coating Thickness: ≥21μm

-

Grade B:

-

Oxide Layer: ≥10μm

-

Paint Film: ≥7μm

-

Total Coating Thickness: ≥16μm

Grade A is typically recommended for exterior applications exposed to sun, rain, or pollution. Grade B is suitable for indoor or semi-exposed areas where durability is still critical but exposure levels are lower.

4. Real-World Applications Across Industries

Electrolytic coated aluminium profiles are used in a wide variety of industries due to their balance of durability, appearance, and workability.

-

Construction: Ideal for window and door frames, curtain walls, cladding systems, and sunshades.

-

Office Interiors: Used in modular partitions, frames, and display structures where aesthetics matter.

-

Industrial Equipment: Applied in mechanical frames, support structures, and protective enclosures.

-

Transportation: Suitable for vehicle bodies or components requiring lightweight and corrosion-resistant materials.

-

Customized Manufacturing: At KaiMeiDa, we support OEM/ODM orders based on customer drawings and specific performance requirements.

5. Why Choose Jiangxi KaiMeiDa Aluminium Profiles?

Our company is located in Phoenix Mountain Industrial Park, Nanchang, covering 200 acres and producing over 40,000 tons annually. We operate:

-

12 advanced aluminium extrusion lines

-

2 spray coating lines

-

2 sandblasting lines

-

4 wood grain transfer lines

-

1 anodized electrophoretic coating line

We implement ISO9001 quality management and ISO14001 environmental standards, using imported testing equipment from Germany and Japan. Our quality control system ensures every profile meets or exceeds the latest national specifications (GB/T 5237.1–6—2017).

Whether you need high-end architectural profiles or customized industrial parts, we deliver consistency, precision, and performance you can trust.

6. Benefits That Go Beyond the Surface

Using electrolytic coated aluminium profiles not only ensures better performance, but also leads to long-term savings and sustainability:

-

Reduced Maintenance: Surfaces remain vibrant and intact for years, reducing repainting or repairs.

-

Lower Installation Costs: Lightweight structure makes transport and assembly easier.

-

Environmental Compliance: Cleaner production processes support green building initiatives.

-

Strong Brand Identity: Beautiful finishes improve perceived product value and project appeal.

At Jiangxi KaiMeiDa, our goal is to help builders and manufacturers elevate their projects with quality that lasts.

Conclusion: Why Electrolytic Coated Aluminium Profiles Are the Future

Whether you're designing a high-rise building, manufacturing industrial frames, or constructing modern interiors, electrolytic coated aluminium profiles offer unmatched benefits in durability, corrosion resistance, finish quality, and sustainability. Compared to traditional metal solutions, they are simply more reliable and cost-effective in the long run.

Jiangxi KaiMeiDa Aluminum is ready to support your next project with tailor-made aluminium profile solutions. Reach out today to discover how our electrolytic coated aluminium profiles can transform your business.

www.jxkmdly.com

Jiangxi KaiMeiDa aluminum