The Key Components of Mechanical Seals: Understanding Their Importance and Functionality

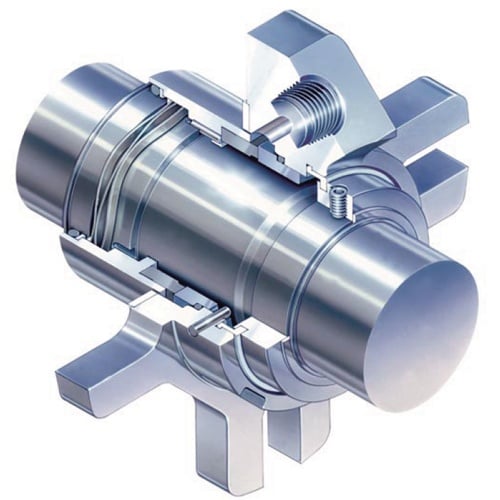

Mechanical seals are critical components in various industrial applications, including pumps, compressors, and mixers. They play a crucial role in preventing leaks and maintaining the integrity of the system. A mechanical seal is a device that seals the gap between two surfaces, preventing the escape of fluids or gases. In this article, we will discuss the most important parts of a mechanical seal and their functions.

- Seal Faces:

The seal faces are the primary components of a mechanical seal. They are the surfaces that come into contact with each other to create a seal. The two seal faces are typically made of hard materials such as ceramic, tungsten carbide, or silicon carbide. The seal faces must be precisely machined to ensure a tight seal and prevent leakage. The quality of the seal faces is critical to the overall performance of the mechanical seal. - Secondary Seals:

Secondary seals are the components that provide additional sealing between the seal faces. They are typically made of elastomers such as Viton or EPDM. The secondary seals prevent the leakage of fluids or gases between the seal faces. They also help to maintain the pressure within the system. - Springs:

Springs are the components that provide the necessary force to keep the seal faces in contact with each other. They are typically made of stainless steel or other corrosion-resistant materials. The springs must be designed to provide the correct amount of force to maintain the seal while allowing for some movement between the seal faces. - Metal Parts:

Metal parts are the components that hold the mechanical seal together. They are typically made of stainless steel or other corrosion-resistant materials. The metal parts must be precisely machined to ensure a tight fit and prevent leakage. They also provide the necessary support for the seal faces and springs. - Gaskets:

Gaskets are the components that provide a seal between the mechanical seal and the housing. They are typically made of soft materials such as rubber or cork. The gaskets prevent leakage between the mechanical seal and the housing.

Conclusion:

In conclusion, the key components of a mechanical seal are the seal faces, secondary seals, springs, metal parts, and gaskets. Each of these components plays a critical role in maintaining the integrity of the system and preventing leaks. It is essential to ensure that each component is of high quality and precisely machined to ensure optimal performance. By understanding the importance and functionality of each component, you can select the right mechanical seal for your specific application.