How Touch Screen Microplate Washers Are Revolutionizing Laboratory Efficiency

In modern laboratories, efficiency and accuracy are paramount. The rise of Touch Screen Microplate Washers has significantly improved workflows, providing users with faster, more precise results. These devices are an essential tool for various laboratory applications, especially in immunoassays such as ELISA (Enzyme-Linked Immunosorbent Assay), where precision in washing microplates is crucial for accurate test results. Companies like Diatek, a global leader in In Vitro Diagnostic (IVD) devices, have embraced touch screen technology to further optimize laboratory operations.

In this blog post, we’ll explore how Touch Screen Microplate Washers are revolutionizing laboratory efficiency, the advantages of incorporating touchscreen technology into lab equipment, and why these washers are an indispensable part of modern laboratories.

What is a Touch Screen Microplate Washer?

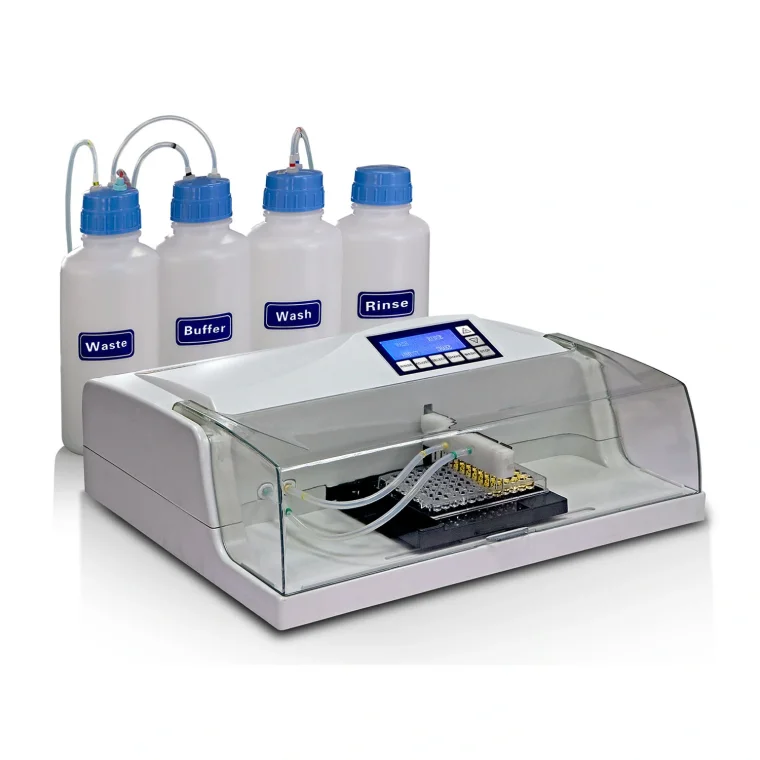

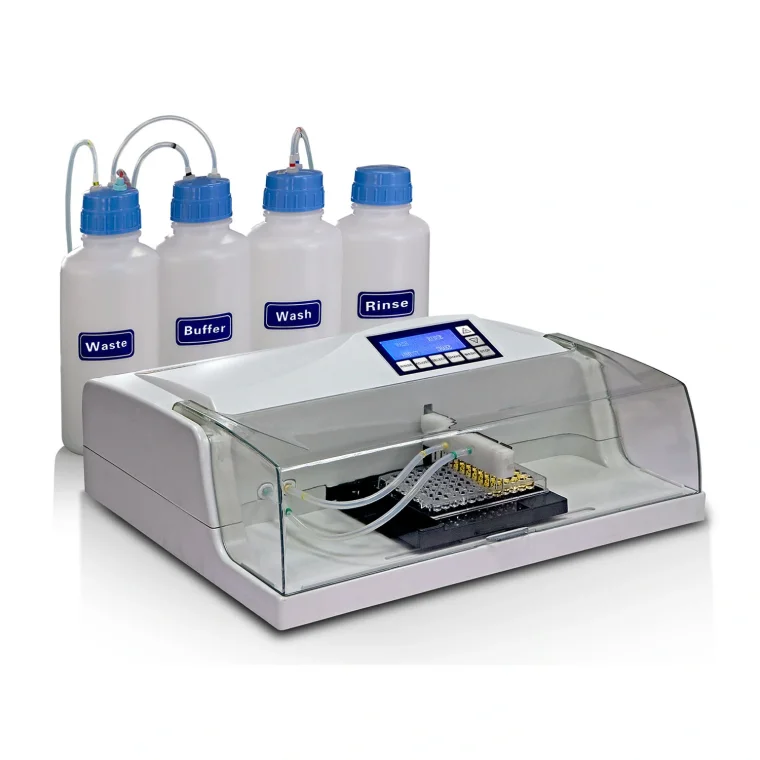

A Microplate Washer is a laboratory instrument designed to clean microplates that are used in assays such as ELISA and other biochemical or diagnostic tests. Microplates, often made up of 96 or 384 wells, are used to carry out tests where multiple samples are processed simultaneously.

The traditional microplate washers required manual operation, leading to potential errors and significant time consumption. However, modern Touch Screen Microplate Washers, like the ones developed by Diatek, are equipped with intuitive touch screen interfaces that allow for easy programming, operation, and monitoring of the washing process.

These washers can efficiently remove residual reagents, wash buffers, and other contaminants from the microplate wells, ensuring that the assays are clean, and the results are reliable. Touchscreen technology makes programming washing protocols and monitoring real-time processes simpler than ever, giving labs more control over their experiments.

Key Features of Touch Screen Microplate Washers

1. User-Friendly Interface

The integration of a touchscreen interface makes operating the microplate washer more intuitive. Instead of relying on complex button presses or knobs, users can quickly select wash protocols, adjust settings, and monitor the progress of the wash cycle with just a few taps. This reduces the learning curve and minimizes human error, ultimately increasing efficiency.

2. Customizable Wash Protocols

Touch screen microplate washers allow users to easily program customizable wash protocols, adjusting parameters such as wash cycles, flow rates, and volumes. This level of flexibility is essential in labs where different assays require varying washing intensities or durations. The ability to set up protocols quickly and recall them as needed speeds up workflows, reducing downtime and increasing productivity.

3. Real-Time Monitoring and Feedback

Touch screen microplate washers can provide real-time feedback on the progress of the washing process, displaying critical information such as cycle time, wash volume, and remaining cycles. This feature is invaluable in high-throughput laboratories where tracking each plate’s progress is essential. The visibility and control offered by the touch screen allow for greater precision in monitoring and adjusting the process, ensuring that each wash cycle is completed accurately.

4. Integration with Lab Information Systems (LIS)

Some advanced touch screen microplate washers, like those from Diatek, can be integrated with Laboratory Information Systems (LIS) and other lab management software. This allows for seamless data collection and tracking, enabling labs to maintain records of each wash cycle. This integration streamlines lab operations, enhances data accuracy, and helps ensure compliance with industry standards and regulations.

5. Time Efficiency

Time is a critical factor in laboratory operations, especially when processing multiple samples. Touch Screen Microplate Washers can complete wash cycles more quickly and accurately than their manual counterparts. By reducing the need for manual intervention and enabling faster setup and protocol adjustments, these devices significantly cut down on overall process time. This helps laboratories achieve higher throughput and more efficient use of resources.

How Touch Screen Microplate Washers Are Revolutionizing Efficiency

1. Increased Throughput and Reduced Downtime

One of the most significant advantages of touch screen microplate washers is their ability to streamline workflows. By automating the washing process and allowing for faster, more efficient protocols, labs can process more samples in less time. This increased throughput is especially valuable in high-demand environments such as hospitals, clinics, research labs, and veterinary clinics, where large volumes of tests need to be conducted daily.

Furthermore, the reliability of touch screen washers minimizes downtime caused by equipment malfunctions or human errors, ensuring that laboratories can continue their work with minimal interruptions.

2. Improved Accuracy and Reproducibility

Consistency is critical in laboratory testing, and touch screen microplate washers help achieve this by precisely controlling wash conditions. By eliminating human error associated with manual washing, these devices ensure that every well in the microplate is washed under identical conditions. This results in improved accuracy and reproducibility, which is essential for obtaining reliable results in immunoassays and diagnostic tests.

3. Ease of Maintenance and Troubleshooting

Touchscreen interfaces often include diagnostic tools and alerts that inform users of any issues with the machine, such as a malfunctioning pump or low wash buffer levels. These proactive warnings help to identify and address issues before they impact laboratory operations, reducing equipment downtime and maintenance costs.

4. Enhanced User Experience

The intuitive interface of touch screen microplate washers improves the overall user experience. Lab technicians can easily navigate through different settings, saving time on setup and reducing the chance of user mistakes. This ease of use fosters better productivity and user satisfaction, leading to more efficient lab operations overall.

The Role of Diatek in Advancing Laboratory Efficiency

Diatek is a global leader in the development and manufacturing of high-quality In Vitro Diagnostic (IVD) devices. The company specializes in the design and production of ELISA microplate readers and microplate washers, which are widely used in hospitals, clinics, disease control centers, blood banks, research laboratories, and veterinary clinics.

With a focus on research and development, manufacturing, and customer service, Diatek continues to provide cutting-edge solutions for enhancing laboratory efficiency. Their commitment to quality is demonstrated through certifications such as ISO9001 and ISO14001, ensuring that their products meet the highest standards of performance and environmental sustainability.

By offering touch screen microplate washers and other advanced diagnostic equipment, Diatek is helping laboratories worldwide improve testing efficiency, reduce errors, and maintain high standards of accuracy.

Conclusion

Touch Screen Microplate Washers are transforming laboratory operations by enhancing efficiency, accuracy, and user control. Their ability to automate and streamline the washing process has revolutionized industries that rely on high-precision assays, such as immunoassays, biochemical testing, and diagnostic testing. Companies like Diatek play a vital role in advancing laboratory technology, providing high-quality products that meet the needs of modern laboratories.

As the demand for faster, more reliable results continues to grow, the integration of touch screen technology into laboratory equipment like microplate washers will only become more important in optimizing workflows, improving productivity, and ensuring accurate, reproducible results.

www.hiwelldiatek.com

Wuxi Huawei Diatek Instrument Co., Ltd.