Challenges and Solutions in Implementing Distributed Temperature Sensing

Distributed Temperature Sensing (DTS) has revolutionized real-time temperature monitoring across multiple industries, providing unprecedented accuracy and the ability to cover vast areas with a single fiber optic line. However, the deployment of DTS systems comes with its own set of challenges. From installation complexities to signal degradation over long distances, companies must carefully plan and implement strategies to maximize efficiency. Shenzhen Mingsheng Electrical Co., Ltd. offers a range of distributed temperature sensing solutions that address these challenges effectively.

Understanding the Challenges

1. Signal Attenuation and Distance Limitations

One of the most common challenges in DTS deployment is signal attenuation. As the optical signal travels along the fiber, its strength gradually decreases, especially over long distances. This can result in inaccurate temperature readings or blind spots in the monitoring network.

2. Environmental Interference

Fiber optic cables are sensitive to external environmental factors such as temperature fluctuations, vibrations, and electromagnetic interference. Harsh conditions, including high temperatures or industrial vibrations, can impact the accuracy and reliability of the DTS system.

3. Complex Installation and Integration

Installing DTS systems often requires careful planning and expertise, particularly in environments with existing infrastructure. Ensuring that fiber optic cables are properly laid, protected, and integrated with other monitoring or control systems can be challenging.

4. Data Management and Interpretation

DTS systems generate large volumes of data, particularly when deployed over extensive pipelines, power grids, or industrial sites. Managing, processing, and interpreting this data in real-time requires robust software solutions and analytics capabilities.

5. Maintenance and Longevity

Maintaining the performance of a DTS system over time is critical. Fiber optic cables may degrade, connectors may loosen, and sensing units may require recalibration. Without proper maintenance, the accuracy of the system can decline, affecting safety and operational efficiency.

Shenzhen Mingsheng Electrical Co., Ltd.’s Solutions

Shenzhen Mingsheng Electrical Co., Ltd. provides an extensive portfolio of products designed to address these challenges. Their solutions not only enhance the accuracy and reliability of DTS systems but also simplify deployment and maintenance.

1. Advanced Fiber Optic Sensors

Mingsheng offers a range of fiber optic sensing devices including DTS, DAS, DVS, BOTDA, and BOTDR systems, as well as fiber Bragg grating sensors and fluorescence fiber sensors. These devices are engineered to minimize signal loss over long distances and provide precise temperature monitoring even in complex environments.

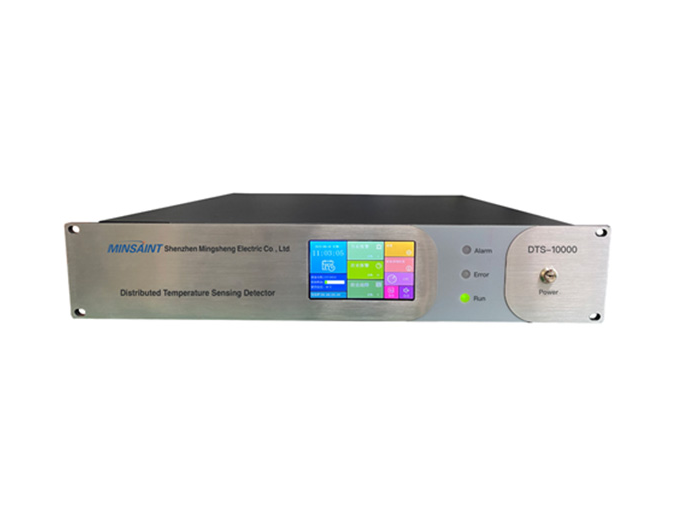

For long-distance monitoring, the DTS-10000 distributed temperature sensing system is particularly noteworthy, offering extended coverage while maintaining high sensitivity and accuracy.

2. Specialized Optical Cables

High-quality sensing cables are essential for minimizing environmental interference. Mingsheng’s temperature-sensing optical cables are designed to withstand industrial conditions, chemical exposure, and extreme temperatures, ensuring consistent performance across challenging environments.

3. Tailored Monitoring Systems

Mingsheng’s solutions extend beyond hardware. They provide tailored monitoring systems such as:

Lithium Battery Rack Fire Detection Systems – Real-time temperature monitoring to prevent early-stage fires.

Power Online Monitoring Systems – Detects abnormal temperature trends in transformers and power lines.

Pipeline Safety Early Warning Systems – Monitors temperature changes for leakage or tampering.

Storage Tank and LNG Temperature Measurement Systems – Ensures safe storage of sensitive materials.

Grain Silo Temperature Measurement Systems – Prevents spoilage by monitoring bulk material temperatures.

Tunnel and Road Monitoring Systems – Detects overheating or fire risks in highways, subways, and underwater tunnels.

Building Fire Online Monitoring Systems – Integrated with early warning and emergency response systems.

Ultra-Early Electrical Fire Detection Systems – Provides preemptive alerts to mitigate risk.

These systems combine advanced fiber optic sensors with intelligent analytics, delivering actionable insights and reliable early warnings.

4. Integration with Smart Technologies

Mingsheng has also pioneered synesthetic technology systems, which integrate DTS data with other environmental and operational metrics. This provides a holistic view of the monitored site, allowing operators to detect anomalies faster and make informed decisions proactively.

5. Comprehensive Support and Maintenance

Recognizing that long-term system reliability is crucial, Mingsheng provides full support services including installation guidance, calibration, and maintenance. This ensures that DTS systems maintain high accuracy and operational efficiency over years of service.

Case Studies of DTS Implementation

Lithium Battery Rack Fire Detection

With the increasing adoption of lithium batteries in energy storage, fire risk management has become a priority. Using Mingsheng’s DTS solutions, facility operators can monitor temperature variations across entire battery racks. The system identifies abnormal hotspots early, triggering alarms before fires occur.

Pipeline Safety Monitoring

For oil and gas pipelines, early leak detection is critical. Mingsheng’s fiber optic monitoring systems detect subtle temperature changes caused by leaks or tampering. The system can cover tens of kilometers of pipeline continuously, providing 24/7 real-time monitoring.

LNG Storage and Transportation

Liquefied natural gas (LNG) is highly sensitive to temperature variations. DTS systems from Mingsheng ensure uniform temperature distribution within storage tanks and along transportation pipelines. This minimizes risk and maintains safety compliance.

Tunnel and Highway Monitoring

Overheating or fire risks in tunnels can escalate quickly. By deploying DTS along the structure, operators can detect abnormal heat patterns and respond promptly. Mingsheng’s robust optical cables ensure uninterrupted monitoring even in extreme underground conditions.

Future Trends in DTS Technology

The DTS industry continues to evolve with innovations in sensor design, signal processing, and AI-driven analytics. Key trends include:

Longer Range Systems – Enhancing signal detection to cover even larger areas without repeaters.

Integration with IoT – DTS data feeding into smart building and industrial IoT platforms.

Predictive Maintenance – Using machine learning to anticipate failures or abnormal temperature trends.

Multi-Parameter Monitoring – Combining temperature sensing with strain, pressure, or chemical detection.

Shenzhen Mingsheng Electrical Co., Ltd. remains at the forefront of these developments, ensuring that customers benefit from reliable, scalable, and cutting-edge DTS solutions.

Conclusion

Implementing distributed temperature sensing systems presents several challenges, including signal attenuation, environmental interference, complex installation, data management, and maintenance. Shenzhen Mingsheng Electrical Co., Ltd. addresses these issues through advanced fiber optic sensors, specialized optical cables, tailored monitoring systems, and comprehensive support services. Their solutions enhance safety, efficiency, and reliability across various industries, from energy storage and power grids to pipelines, tunnels, and buildings. By leveraging these solutions, organizations can achieve real-time, accurate, and actionable temperature monitoring that safeguards people, assets, and operations.

For those interested in exploring long-distance DTS solutions, Mingsheng’s DTS-10000 system is a proven option that delivers high-performance monitoring across extensive infrastructure networks.

www.minsaint.com

Shenzhen Mingsheng Electrical Co ., Ltd. ( MINSAINT)