Bucket Processing Service: Key to Durable and Efficient Excavator Buckets

Excavator buckets are vital components in industries like construction, mining, and agriculture. Their durability and efficiency directly affect the productivity of heavy machinery and project success. A professional bucket processing service is essential to ensure that excavator buckets meet rigorous standards for performance and longevity. Hangzhou Hengli Metal Processing Co., Ltd., a modern enterprise specializing in metal supply chain integration, provides top-tier bucket processing services tailored to diverse industry needs. This article explores why bucket processing services are key to durable and efficient excavator buckets and how Hengli meets these demands with advanced technology and custom solutions.

1. What Is Bucket Processing Service?

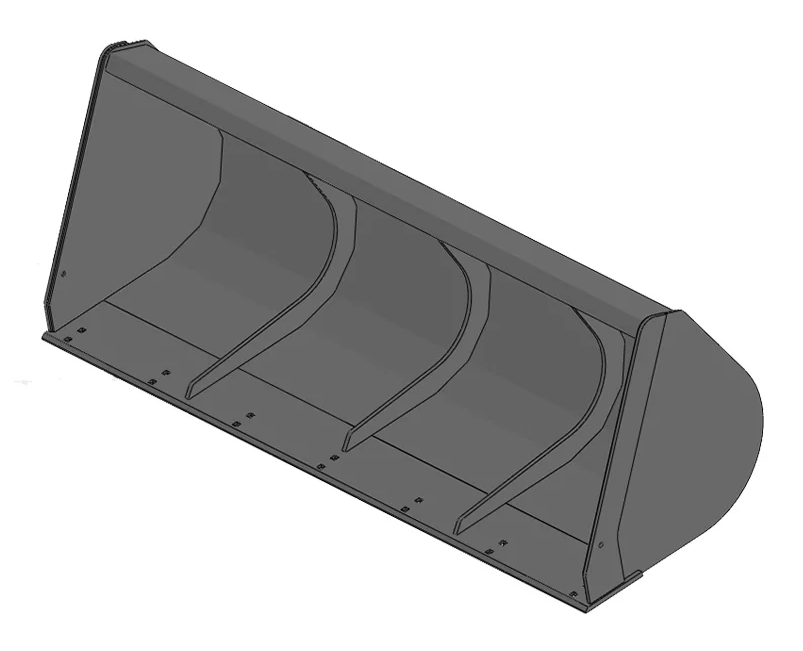

Bucket processing service involves a series of manufacturing and maintenance steps designed to create, repair, or upgrade excavator buckets. The process typically includes cutting, shaping, welding, painting, and finishing. These steps ensure that buckets are not only structurally sound but also optimized for specific working conditions. Hengli specializes in manufacturing various heavy machinery attachments, including buckets, arms, grapples, and rotary actuators, leveraging state-of-the-art equipment and skilled professionals to deliver superior quality.

2. Why Quality Bucket Processing Matters

Excavator buckets are exposed to harsh environments and heavy loads daily. Substandard manufacturing or poor maintenance can lead to premature wear, cracks, and equipment failure, resulting in costly downtime. High-quality bucket processing services ensure that buckets are fabricated or repaired with precision, using durable materials and advanced techniques. Hengli’s bucket processing focuses on enhancing structural integrity and wear resistance, which translates into longer service life and reliable performance on site.

3. Tailored Solutions for Diverse Industries

Different industries impose unique demands on excavator buckets. For instance, mining requires buckets that resist abrasive materials, while agricultural applications might need buckets designed for lighter loads but higher precision. Hengli understands these varied requirements and works closely with clients to customize bucket designs and processing techniques. This client-centric approach ensures that every bucket delivered meets the exact functional and environmental needs of industries such as construction, mining, agriculture, and energy.

4. Advanced Technology and Techniques in Bucket Processing

Hengli employs cutting-edge machinery and technology to ensure the highest quality standards in bucket processing. This includes laser cutting for precise shaping, robotic welding for consistent and strong joints, and advanced painting methods to provide corrosion resistance. The combination of technology and expert craftsmanship enables Hengli to produce buckets that stand up to extreme wear and tear while maintaining dimensional accuracy. These capabilities allow Hengli to handle bulk production as well as specialized custom orders efficiently.

5. Comprehensive Bucket Repair and Maintenance Services

Apart from fabrication, Hengli offers professional bucket repair and maintenance services to extend the life of existing equipment. The expert team can diagnose issues such as cracks, worn edges, or deformations, and apply appropriate welding, reinforcement, or reshaping techniques to restore bucket functionality. Timely repairs help prevent unexpected failures and keep machinery operating at peak efficiency, saving costs and minimizing downtime for clients.

6. Hengli’s Commitment to Quality and Customer Satisfaction

At Hengli, customer satisfaction is paramount. The company combines modern technology, skilled personnel, and a deep understanding of client needs to deliver bucket processing services that exceed expectations. Hengli’s integrated supply chain approach ensures smooth project management and timely delivery. Clients benefit from a one-stop-shop experience, as Hengli also offers related services including machining, welding, and fabrication. This comprehensive offering helps clients optimize their operations with reliable, cost-effective solutions.

Conclusion: Why Bucket Processing Service Is Essential for Durable and Efficient Excavator Buckets

Bucket processing service is a cornerstone for ensuring excavator buckets are durable, efficient, and tailored to the demanding environments they work in. Hangzhou Hengli Metal Processing Co., Ltd. exemplifies how modern technology, skilled expertise, and customer-focused customization come together to deliver exceptional bucket processing services. Whether fabricating new buckets or repairing existing ones, Hengli helps industries like construction, mining, agriculture, and energy maintain high operational standards and reduce costly downtime. For those seeking reliable, high-quality bucket processing service, Hengli stands out as a trusted partner ready to meet your industrial needs with professionalism and excellence.

www.hlmetal.net

HENGLI