The Intricate Process of Manufacturing Recycled Electronics

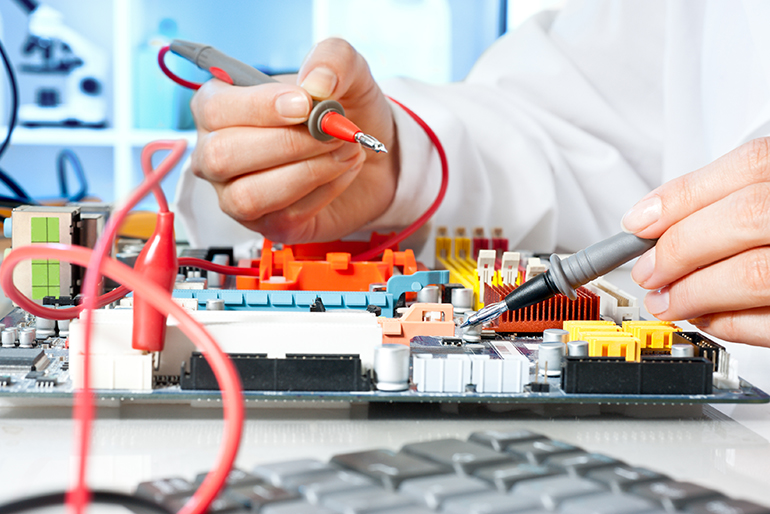

Tech tests electronic equipment in service centre

In today's fast-paced world, electronic devices have become an integral part of our lives. However, the rapid advancement of technology has led to a significant increase in electronic waste. To combat this issue, the recycling of electronics has gained immense importance. In this blog post, we will delve into the intricate process of how recycled electronics are made, ensuring both environmental sustainability and resource conservation.

- Collection and Sorting:

The first step in the recycling process is the collection and sorting of electronic waste. This involves the careful collection of discarded devices from various sources such as households, businesses, and recycling centers. The collected waste is then sorted based on its type, size, and material composition. - Dismantling and Component Extraction:

Once the electronic waste is sorted, it undergoes a meticulous dismantling process. Skilled technicians disassemble the devices, separating them into individual components such as circuit boards, batteries, cables, and plastic casings. This step requires expertise to ensure the safe removal of hazardous materials like lead, mercury, and cadmium. - Material Recovery:

After dismantling, the extracted components undergo material recovery. Circuit boards, for instance, are processed through a specialized technique called electronic waste recycling. This process involves the use of chemicals to dissolve the board and separate valuable metals like gold, silver, and copper. These recovered materials can then be reused in the manufacturing of new electronic devices. - Plastic Recycling:

Plastic casings and other non-metal components are sent for plastic recycling. The plastics are sorted by type and then shredded into small pieces. These pieces are melted and molded into pellets, which can be used as raw materials for manufacturing new plastic products. - Battery Recycling:

Batteries, a significant component of electronic waste, require special attention due to their potential environmental hazards. Battery recycling involves the safe extraction of valuable metals like lithium, cobalt, and nickel. These metals can be reused in the production of new batteries or other applications. - Quality Control and Testing:

Once the materials are recovered, they undergo rigorous quality control and testing procedures. This ensures that the recycled components meet the required standards for use in new electronic devices. Any defective or non-compliant components are further processed or disposed of properly.

Conclusion:

The process of manufacturing recycled electronics is a complex and intricate one. It involves careful collection, sorting, dismantling, material recovery, and quality control. By recycling electronic waste, we not only reduce the environmental impact but also conserve valuable resources. As technology continues to advance, it is crucial to embrace sustainable practices like electronic recycling to create a greener and more sustainable future.