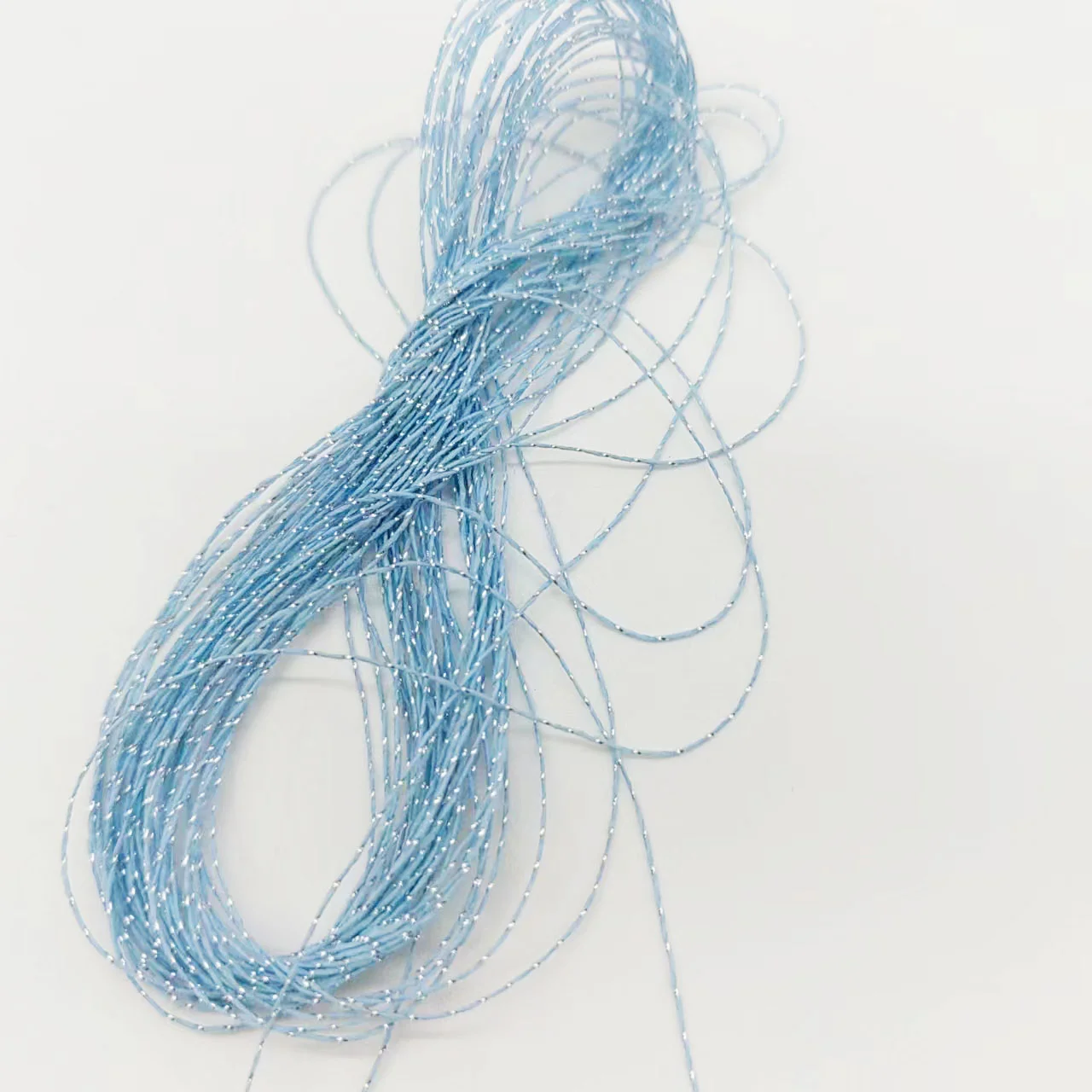

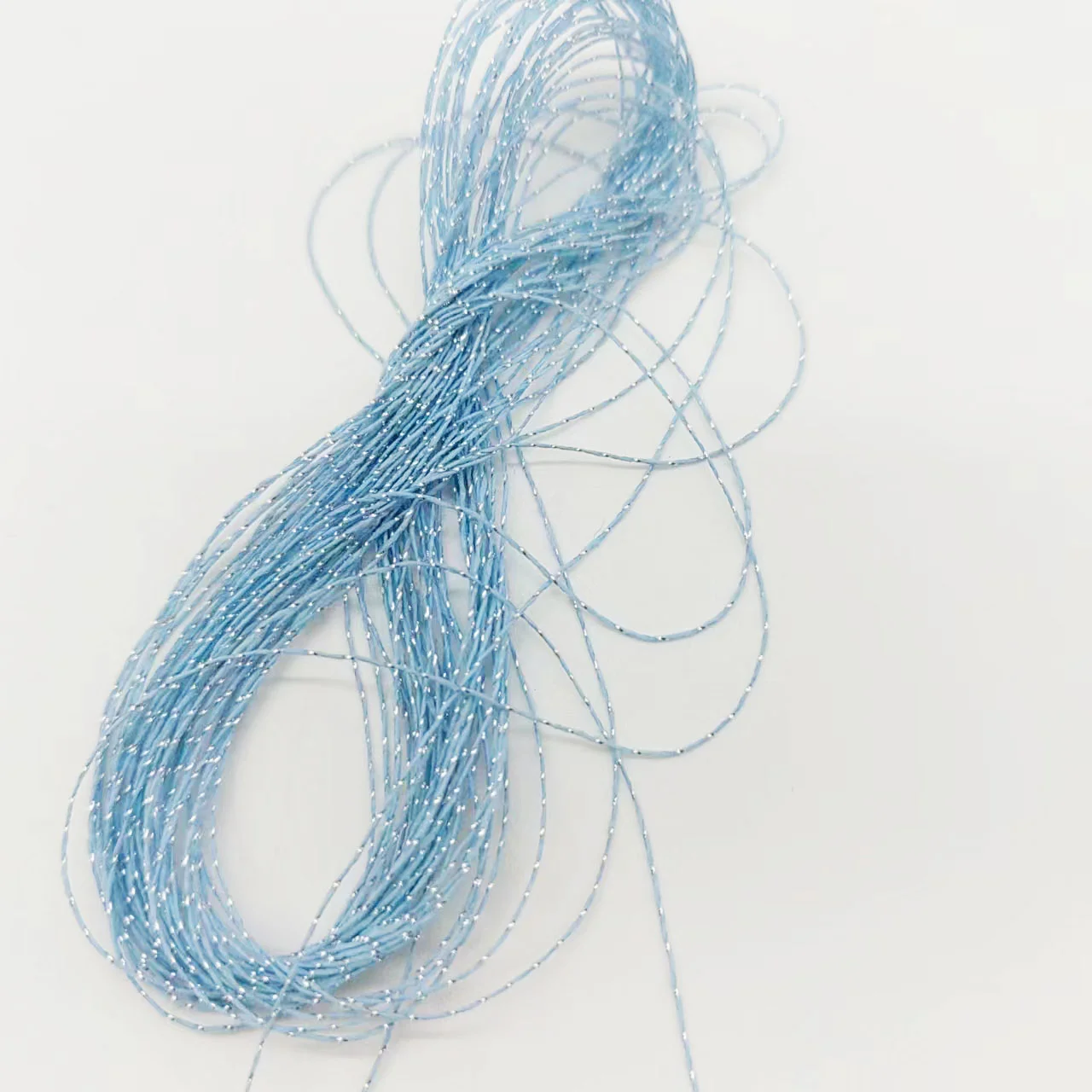

Understanding Dyeing Methods for Dyed Twist Yarn: Reactive, Disperse, Sulfur, and Pigment Dyeing

Dyed twist yarn plays a crucial role in the textile industry, offering a variety of colors and finishes that enhance the aesthetic and functional properties of fabrics. The dyeing process significantly impacts the yarn’s quality, colorfastness, and application. There are several dyeing methods used for twisted yarns, with reactive dyes, disperse dyes, sulfur dyes, and pigment dyeing being the most common. Each method has its unique characteristics, advantages, and best-use cases. This article will provide an in-depth look at these dyeing techniques and their applications in the textile industry.

1. Reactive Dyeing

What Is Reactive Dyeing?

Reactive dyeing is a process where the dye chemically bonds with the fiber, creating a strong and permanent coloration. This method is most commonly used for natural fibers like cotton, viscose, and wool.

Advantages of Reactive Dyeing:

✔ Excellent colorfastness – The dye forms a covalent bond with the fiber, making it resistant to washing and light.

✔ Bright and vibrant colors – Reactive dyes provide a wide color range with high brilliance.

✔ Soft hand feel – The dyed yarn retains a smooth and comfortable texture.

Disadvantages:

❌ Requires precise pH and temperature control.

❌ Uses a large amount of water, making wastewater treatment necessary for sustainability.

Common Applications:

-

Cotton-based dyed twist yarn for apparel fabrics, home textiles, and knitting.

-

Blended yarns with a high percentage of natural fibers.

2. Disperse Dyeing

What Is Disperse Dyeing?

Disperse dyes are water-insoluble dyes used primarily for synthetic fibers such as polyester, acetate, and nylon. These dyes are applied through high-temperature dyeing or sublimation techniques.

Advantages of Disperse Dyeing:

✔ Ideal for synthetic fibers – The only suitable dyeing method for polyester yarn.

✔ Good wash and lightfastness – Provides strong resistance to fading.

✔ Applicable for sublimation printing – Can be transferred to fabrics using heat.

Disadvantages:

❌ High-temperature dyeing requires energy-intensive processes.

❌ Color matching can be challenging due to limited shade options.

Common Applications:

-

Polyester dyed twist yarn used in sportswear, upholstery, and outdoor textiles.

-

Functional textiles that require UV resistance, moisture-wicking, and durability.

3. Sulfur Dyeing

What Is Sulfur Dyeing?

Sulfur dyes are inexpensive and widely used for dyeing cellulose fibers, particularly cotton and viscose. These dyes create deep shades, particularly blacks, blues, and browns.

Advantages of Sulfur Dyeing:

✔ Cost-effective – Sulfur dyes are cheaper compared to reactive dyes.

✔ Good wash fastness – Once oxidized, the color remains stable.

✔ Suitable for dark colors – Produces deep and rich tones.

Disadvantages:

❌ Poor lightfastness – Colors can fade when exposed to sunlight.

❌ Brittle fibers – Prolonged exposure to sulfur dyes can weaken yarns.

Common Applications:

-

Cotton-based dyed twist yarn for denim, workwear, and industrial fabrics.

-

Heavy-duty textiles where cost efficiency is a priority.

4. Pigment Dyeing

What Is Pigment Dyeing?

Unlike traditional dyes that penetrate fibers, pigment dyes adhere to the surface of the yarn using a binder. Pigments are versatile and can be used on all fiber types, making them highly adaptable.

Advantages of Pigment Dyeing:

✔ Can be applied to all fiber types – Works well with cotton, polyester, and blends.

✔ Good color vibrancy – Produces bold and striking shades.

✔ Eco-friendly options available – Low-water and digital printing applications reduce waste.

Disadvantages:

❌ Lower wash fastness – Pigments can fade over time with repeated washing.

❌ Stiff hand feel – The binder may leave a rough texture on the fabric.

Common Applications:

-

Fashion textiles that require vintage, faded, or distressed effects.

-

Textile printing applications where multi-fiber dyeing is needed.

Comparison Table of Dyeing Methods

| Dyeing Method | Suitable Fibers | Fastness | Key Benefits | Common Applications |

|---|---|---|---|---|

| Reactive Dyeing | Cotton, viscose, wool | High | Vibrant colors, strong bonding | Apparel, home textiles |

| Disperse Dyeing | Polyester, nylon, acetate | High | Best for synthetics, durable | Sportswear, upholstery |

| Sulfur Dyeing | Cotton, rayon | Moderate | Cost-effective, deep colors | Denim, workwear |

| Pigment Dyeing | All fibers | Low to moderate | Versatile, bright colors | Fashion, prints |

The choice of dyeing method for dyed twist yarn depends on the fiber type, desired color properties, durability needs, and environmental considerations. Reactive dyes offer excellent colorfastness for natural fibers, disperse dyes are best for synthetics, sulfur dyes provide cost-effective deep shades, and pigment dyes are versatile but have lower wash durability.

Sustainability and Innovation at Hangzhou Futureyarn Textile Co., Ltd.

Hangzhou Futureyarn Textile Co., Ltd. is committed to leading the way in sustainable and innovative dyeing techniques within the textile industry. We specialize in adopting cutting-edge technologies such as biodegradable pigments, and energy-efficient dyeing processes. These advancements significantly reduce the environmental impact while ensuring that the dyed twist yarn maintains the highest standards of quality, color vibrancy, and durability.

www.futureyarn.com

Hangzhou Futureyarn Textile Co.,Ltd.