How PVC Foam Regulators Enhance the Quality and Durability of Foam Products

In the production of foam products, whether for construction, automotive, or packaging industries, achieving the right balance of quality, durability, and performance is essential. This is where PVC foam regulators come into play. These specialized additives play a crucial role in enhancing the characteristics of foam products, ensuring that they meet both the functional and aesthetic needs of various applications.

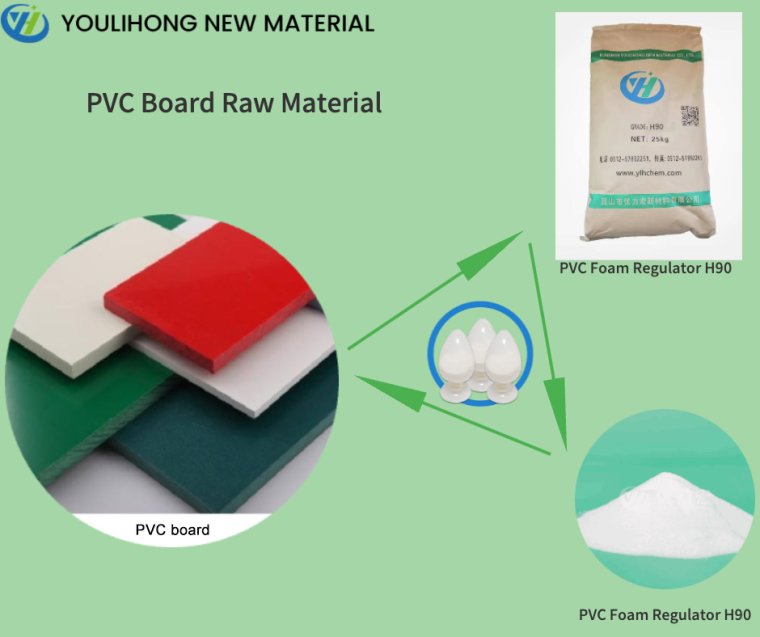

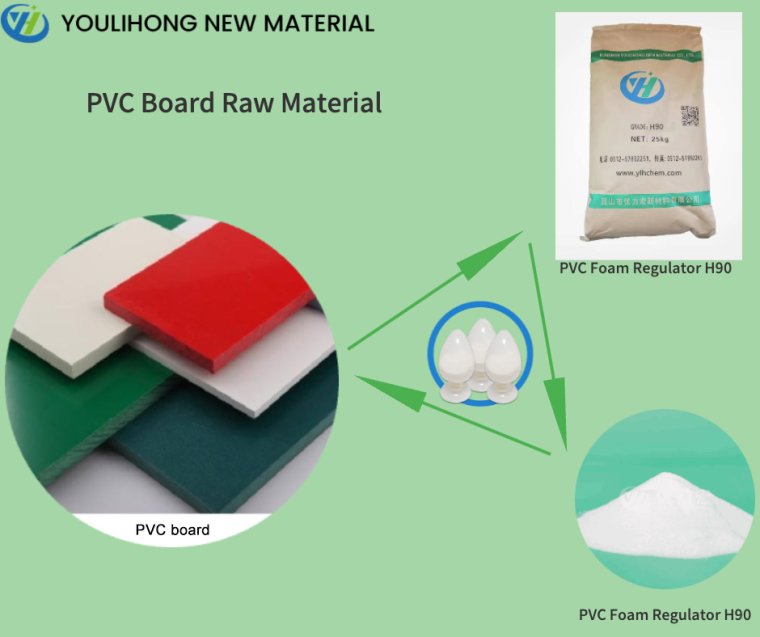

In this article, we’ll explore how PVC foam regulators enhance the quality and durability of foam products, and how companies like Youlihong New Material Co., Ltd., a leader in PVC processing additives, are improving foam production with their advanced solutions.

What Are PVC Foam Regulators?

PVC foam regulators are chemical additives designed to control and optimize the foaming process during the production of PVC-based foamed materials. These regulators ensure that the foam structure is uniform and stable, giving the final product desirable qualities such as excellent mechanical strength, smooth texture, and enhanced durability.

In essence, a PVC foam regulator helps regulate the foaming action by controlling the expansion of air bubbles, the formation of cell structures, and the overall density of the foam. By adjusting these factors, manufacturers can achieve the desired physical properties, such as flexibility, resilience, and thermal insulation.

The Role of PVC Foam Regulators in Enhancing Quality

1. Improved Foam Uniformity and Consistency

One of the most important functions of a PVC foam regulator is its ability to improve the uniformity of the foam. Inconsistent foaming can lead to irregularities in the structure of the foam, such as uneven cell distribution or weak spots, which can compromise the overall quality of the product.

With the use of a PVC foam regulator, manufacturers can achieve a consistent cell size and uniform foam structure, which results in a more reliable and high-quality product. This is especially important in applications where uniformity and consistency are key to performance, such as in insulation materials or packaging products.

Youlihong New Material Co., Ltd., with its expertise in PVC processing additives, including PVC foam regulators, provides solutions that help achieve consistent foam quality across a range of applications.

2. Enhanced Durability and Mechanical Properties

PVC foam products need to meet specific mechanical requirements, such as impact resistance, flexibility, and tensile strength. PVC foam regulators play a significant role in improving the mechanical properties of the final foam product by promoting a more stable and dense cell structure.

When the foam structure is optimized, the resulting product becomes more durable and able to withstand mechanical stresses, including impacts, pressure, and wear. This is particularly important in the construction, automotive, and furniture industries, where durability is a critical factor.

Using PVC foam regulators, manufacturers can produce foam products that retain their shape and strength over time, ensuring longevity and reliability even under demanding conditions.

3. Optimized Foam Density for Specific Applications

Another key benefit of PVC foam regulators is their ability to control the density of the foam. Foam density is critical to the performance of the product, and depending on the application, it may need to be lightweight for easier handling or denser for greater strength and insulation.

For instance, in thermal insulation applications, a denser foam may be preferred for better heat resistance, while in packaging or cushioning, a lighter foam may be more appropriate. PVC foam regulators give manufacturers the flexibility to adjust foam density according to specific performance needs, ensuring that the final product is perfectly suited for its intended use.

Youlihong New Material Co., Ltd. specializes in providing PVC processing additives, such as foam regulators and calcium-zinc stabilizers, that allow manufacturers to tailor the density and overall quality of their PVC foam products for a wide range of industries.

How PVC Foam Regulators Contribute to Environmental Sustainability

In addition to enhancing product quality, PVC foam regulators also support sustainability efforts in foam production. These additives can help reduce the overall consumption of raw materials by optimizing the foaming process, allowing manufacturers to produce foam with the ideal balance of properties while minimizing material waste.

Moreover, PVC foam products that are optimized with the help of these regulators often exhibit better performance characteristics, such as thermal insulation and soundproofing, which can contribute to energy efficiency in applications such as building insulation or automotive parts.

Youlihong New Material Co., Ltd. is committed to promoting environmentally friendly solutions in the PVC industry by developing advanced additives, such as foam regulators and defoamers, that improve production efficiency while reducing environmental impact.

Why Choose Youlihong New Material Co., Ltd.?

With years of experience in developing and manufacturing high-quality PVC processing additives, Youlihong New Material Co., Ltd. is a trusted leader in the industry. Their product portfolio includes a wide range of solutions, from SPC processing aids and calcium-zinc stabilizers to foam regulators and defoamers.

Their PVC foam regulators are specifically designed to enhance the quality and performance of foam products, ensuring that manufacturers can achieve high-quality, durable, and reliable materials for a variety of applications. With a focus on customization, research and development, and customer satisfaction, Youlihong is well-equipped to meet the unique needs of the PVC industry.

Conclusion

PVC foam regulators are essential additives that significantly enhance the quality, durability, and performance of foam products. By improving foam uniformity, mechanical properties, and density, these regulators allow manufacturers to produce high-quality, reliable products for a variety of industries, including construction, automotive, and packaging.

Companies like Youlihong New Material Co., Ltd., with their expertise in PVC processing additives, provide manufacturers with the tools they need to create foam products that meet the highest standards of quality and performance. By incorporating PVC foam regulators into their production processes, manufacturers can ensure that their foam products deliver exceptional results and long-lasting durability.

www.ylhchem.com

Youlihong New Material(KunShan) Co.,Ltd.