Orbital Welding Machines for Precision Welding in Oil & Gas Industry

In the highly demanding oil and gas industry, precision and reliability are not optional—they are essential. The industry relies heavily on robust piping systems, critical structural components, and high-pressure vessels. In such applications, the quality of welds can make the difference between operational efficiency and catastrophic failure. This is where orbital welding machines come into play, offering unparalleled precision, repeatability, and safety in welding operations.

What Are Orbital Welding Machines?

Orbital welding machines are automated welding systems designed to rotate a welding torch around a stationary pipe or tube, allowing for a consistent and high-quality weld. Unlike traditional manual welding, orbital welding systems reduce human error by controlling critical welding parameters such as speed, current, and voltage automatically. These machines can be used for both TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding processes, with TIG being the most common in precision applications.

The key features of orbital welding machines include:

-

Automated torch rotation for uniform welds.

-

Programmable welding parameters to ensure consistency.

-

High precision control suitable for thin-walled pipes and critical joints.

-

Repeatability, which is essential for mass production or long pipeline runs.

Why Precision Welding Matters in Oil & Gas

The oil and gas industry operates under extreme conditions, including high pressure, corrosive environments, and fluctuating temperatures. Weld failures in pipelines or refinery equipment can lead to leaks, environmental hazards, and costly downtime. Precision welding ensures that each joint meets strict industry standards such as ASME, ISO, and API.

Applications in Oil & Gas:

-

Pipeline Construction: Pipelines transporting crude oil, natural gas, and refined products require consistent welds along thousands of kilometers. Orbital welding machines provide the uniformity needed to minimize weak points and potential leaks.

-

Refinery Equipment: High-pressure vessels, heat exchangers, and storage tanks need welds that can withstand temperature fluctuations and corrosive chemicals. Orbital welding ensures structural integrity and compliance with safety regulations.

-

Offshore Platforms: Offshore drilling and processing platforms operate in harsh marine environments. Welding precision is critical for pipelines, risers, and structural components exposed to saltwater and high stress.

Advantages of Using Orbital Welding Machines in Oil & Gas

1. Superior Weld Quality

Orbital welding machines achieve consistent penetration and bead profiles, reducing defects like porosity, cracks, and undercutting. This consistency is crucial in oil and gas applications where the failure of a single weld can have catastrophic consequences.

2. High Efficiency and Productivity

Manual welding requires skilled labor, which can be limited and expensive. Orbital welding machines automate the process, allowing operators to focus on monitoring and quality control. This leads to faster production cycles and lower labor costs.

3. Enhanced Safety

Welding in oil and gas facilities often involves confined spaces, high-pressure systems, and hazardous environments. By automating welding, orbital machines reduce the risk of human exposure to heat, fumes, and potential accidents.

4. Compliance with Industry Standards

Orbital welding machines can be programmed to meet stringent codes such as ASME Section IX for pressure vessels or API 1104 for pipeline welding. This ensures that every weld meets regulatory requirements, reducing the risk of inspection failures.

5. Repeatability Across Multiple Sites

Oil and gas projects often span multiple facilities or locations. Using standardized orbital welding machines allows companies to maintain consistent weld quality across different sites, facilitating easier maintenance and inspection.

Types of Orbital Welding Machines Used in Oil & Gas

1. Single-Head Orbital Welding Machines

Single-head machines are suitable for smaller diameter pipes and simple welding applications. They offer precise control and are easier to transport and set up, making them ideal for maintenance or repair work in refineries and offshore platforms.

2. Dual-Head Orbital Welding Machines

Dual-head systems are designed for larger pipes and high-volume welding tasks. They can weld from two sides simultaneously, increasing efficiency and reducing total welding time. These machines are often used in pipeline construction projects where large-diameter pipes are common.

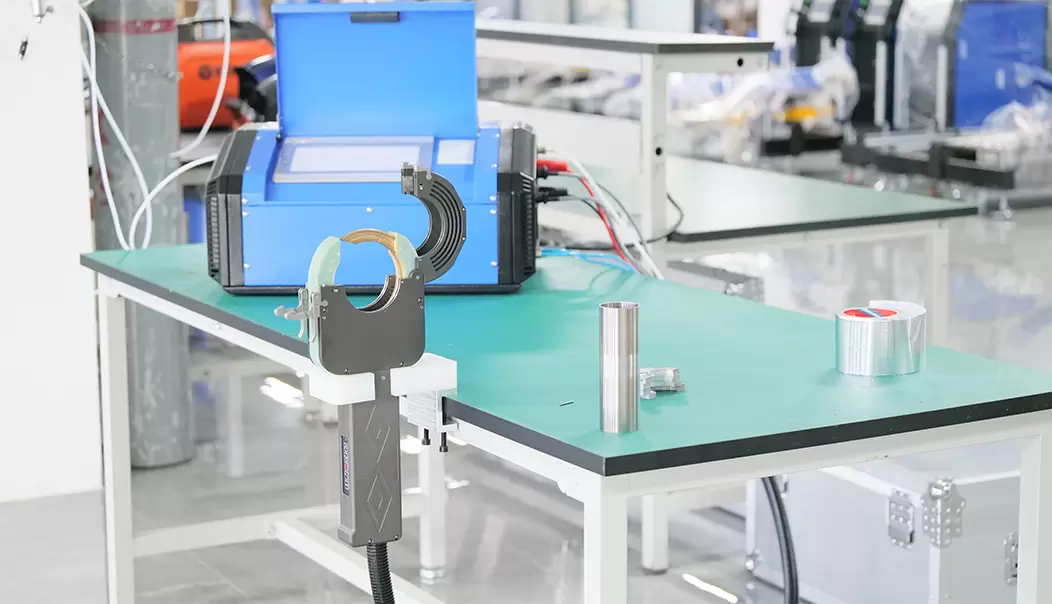

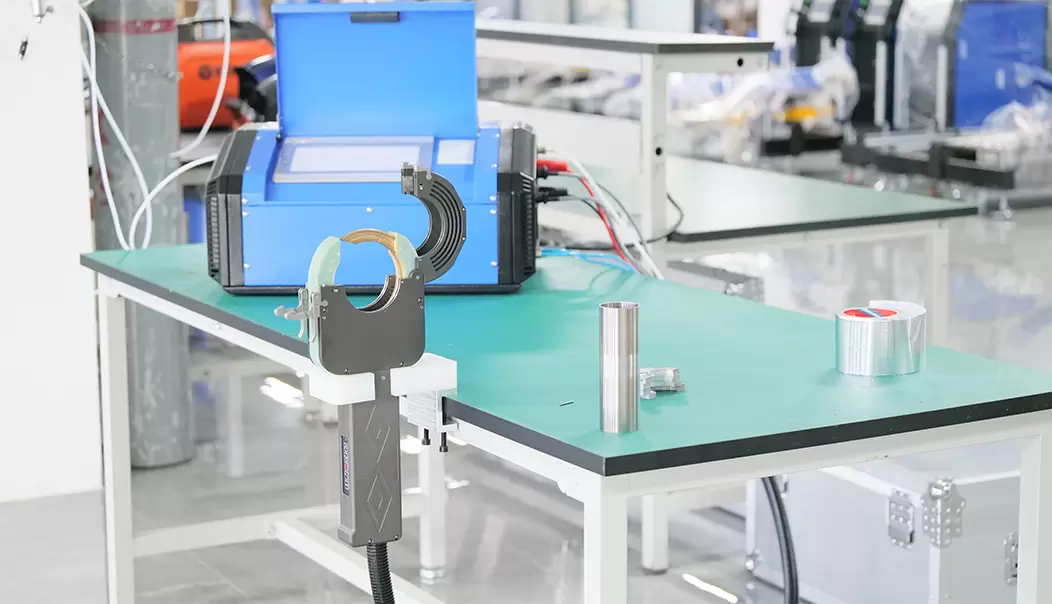

3. Portable Orbital Welding Machines

Portability is crucial for on-site welding in remote oil fields or offshore platforms. Portable orbital welding machines are lightweight, easy to set up, and can operate on-site with minimal infrastructure.

4. Automated CNC Orbital Welding Systems

For large-scale fabrication plants, automated CNC orbital welding systems integrate robotics and computer control for maximum precision. These systems can store welding programs, monitor process parameters, and adjust in real-time, ensuring repeatable and defect-free welds.

Challenges and Considerations

While orbital welding machines provide numerous benefits, oil and gas companies must consider several factors before implementation:

-

Initial Investment: High-quality orbital welding machines can be expensive, though the long-term ROI often justifies the cost due to reduced defects and labor savings.

-

Operator Training: Skilled technicians are still required to program, monitor, and maintain the machines. Proper training ensures optimal performance.

-

Material Compatibility: Different materials, such as stainless steel, carbon steel, and nickel alloys, require tailored welding programs to achieve perfect results.

-

Pipe Preparation: Accurate pipe alignment and cleaning are essential to ensure high-quality welds, especially for thin-walled or high-pressure pipes.

Maintenance and Calibration

Regular maintenance and calibration are critical for ensuring that orbital welding machines perform reliably:

-

Routine Cleaning: Remove slag, dust, and debris from the welding torch and clamping system.

-

Parameter Verification: Regularly check current, voltage, and rotation speed to maintain precision.

-

Component Inspection: Inspect motors, gears, and cables for wear or damage.

-

Software Updates: Keep control software up-to-date to benefit from the latest welding algorithms and safety features.

Conclusion

In the oil and gas industry, the importance of precision welding cannot be overstated. Orbital welding machines provide unmatched accuracy, repeatability, and safety, making them indispensable tools for modern pipelines, refineries, and offshore platforms. By automating the welding process, companies can achieve consistent weld quality, improve operational efficiency, and ensure compliance with stringent industry standards.

For any oil and gas operation looking to reduce defects, enhance productivity, and maintain safety, investing in orbital welding machines is not just a choice—it is a necessity.

NODHA, as a professional supplier of orbital welding machines, is committed to providing high-precision welding solutions for the oil and gas industry. With advanced automation technology and stringent quality control, NODHA's equipment not only ensures welding consistency for pipelines and high-pressure equipment but also significantly improves production efficiency and safety, providing strong support for customers to achieve reliable and efficient welding operations under complex working conditions.

https://www.nodha.com/blog/orbital-welding-machines-for-precision-welding-in-oil-gas-industry.html

nodha