How to Select the Right A283 Carbon Steel Coil for Your Manufacturing Needs

Selecting the right steel material is a critical decision that directly affects product performance, manufacturing efficiency, and overall project cost. Among commonly used carbon steels, A283 carbon steel coil is widely applied in general structural and pressure-related applications due to its balanced mechanical properties and cost-effectiveness. However, choosing the right grade and specification requires a clear understanding of your manufacturing needs and application environment.

This article explains how to select the appropriate A283 carbon steel coil and how experienced metal suppliers such as Fuchuan Metal Co., Ltd. can support manufacturers with reliable material solutions across multiple industries.

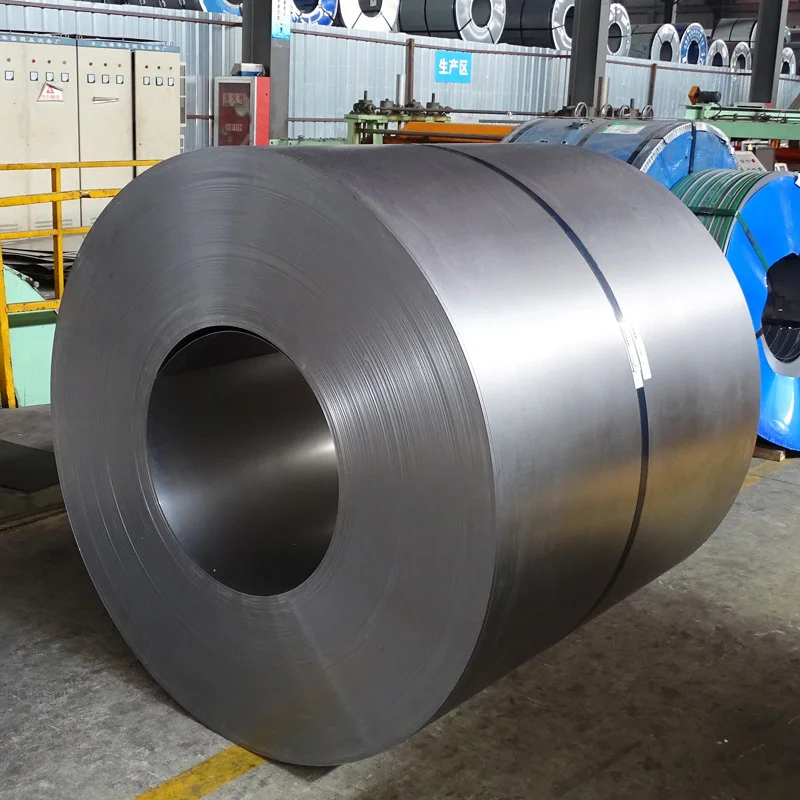

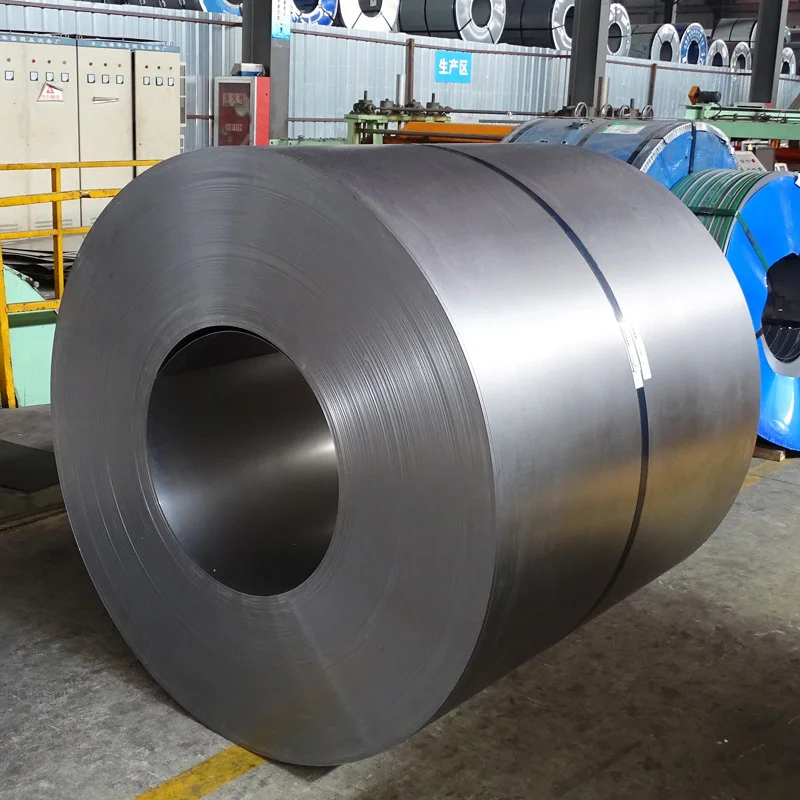

Understanding A283 Carbon Steel Coil

ASTM A283 carbon steel is primarily used for low to intermediate strength structural applications. It is available in several grades, typically Grade A, B, C, and D, each offering different tensile strength and yield characteristics. Supplied in coil form, A283 carbon steel is suitable for further processing such as cutting, forming, welding, and fabrication.

Key characteristics of A283 carbon steel coil include:

-

Good weldability and formability

-

Stable mechanical performance

-

Cost-efficient material choice

-

Wide availability for general-purpose applications

These features make it a popular option for manufacturers seeking dependable performance without excessive material costs.

Define Your Application Requirements

The first step in selecting the right A283 carbon steel coil is clearly defining how it will be used. Consider factors such as:

-

Structural load requirements

-

Operating temperature and pressure

-

Exposure to corrosive environments

-

Fabrication methods such as welding or bending

For example, components used in storage tanks or low-pressure vessels may require higher strength grades like A283 Grade C or D, while lighter structural parts may perform well with Grade A or B.

Choose the Appropriate Grade

Each A283 grade is designed for specific strength requirements:

-

Grade A & B: Suitable for low-strength structural applications where ease of fabrication is prioritized

-

Grade C: Offers higher tensile strength and is commonly used in industrial equipment and fabricated structures

-

Grade D: Provides the highest strength among A283 grades for more demanding applications

Selecting the correct grade ensures sufficient safety margins while avoiding unnecessary material costs.

Consider Thickness, Width, and Coil Specifications

Manufacturing efficiency depends heavily on choosing the right coil dimensions. Thickness and width should match your processing equipment and final product design to minimize waste and secondary processing.

High-quality suppliers can provide A283 carbon steel coils in customized specifications, helping manufacturers improve yield and reduce production time.

Evaluate Surface Condition and Processing Needs

Surface quality can impact downstream processing such as coating, painting, or further forming. Depending on your application, you may require hot-rolled or pickled and oiled finishes to meet performance and appearance requirements.

Discussing these needs in advance with your supplier helps ensure the steel coil is delivered ready for your production line.

Quality Assurance and Standards Compliance

Reliable performance starts with consistent quality. Ensure that the A283 carbon steel coil meets relevant ASTM standards and comes with proper inspection documentation such as mill test certificates.

Working with a professional metal supplier ensures traceability, stable quality, and compliance with international standards—essential for industries with strict technical requirements.

Partnering with a Professional Metal Supplier

Although A283 carbon steel is the focus of this article, many manufacturing projects involve multiple materials. Fuchuan Metal Co., Ltd., as a professional metal export trading company, offers a broad product portfolio including stainless steel coils, stainless steel plates, stainless steel pipes, high-temperature alloys, Hastelloy, nickel-based alloys, as well as aluminum and copper products.

Its materials are widely applied in industries such as chemical processing, petroleum, synthetic fiber production, papermaking, natural gas, nuclear power, boiler heat exchangers, shipbuilding, food machinery, environmental protection, construction, and aerospace. This multi-material expertise allows customers to source complementary materials efficiently while maintaining consistent quality standards.

Balancing Cost and Long-Term Performance

While A283 carbon steel coil is valued for its affordability, selecting the right grade and specification helps avoid premature wear, rework, or safety risks. A well-matched material choice reduces maintenance costs and improves long-term reliability.

An experienced supplier can help evaluate cost-performance trade-offs and recommend solutions that align with both budget and technical goals.

Conclusion

Choosing the right A283 carbon steel coil requires a clear understanding of application demands, grade selection, dimensional requirements, and quality standards. By carefully matching these factors to your manufacturing needs, you can achieve efficient production and reliable product performance.

With extensive experience supplying a wide range of metal materials across diverse industries, Fuchuan Metal Co., Ltd. supports manufacturers with professional sourcing, consistent quality, and flexible material solutions that help projects move forward with confidence.

www.fuchuansteel.com

Fuchuan Metal Co., Ltd.