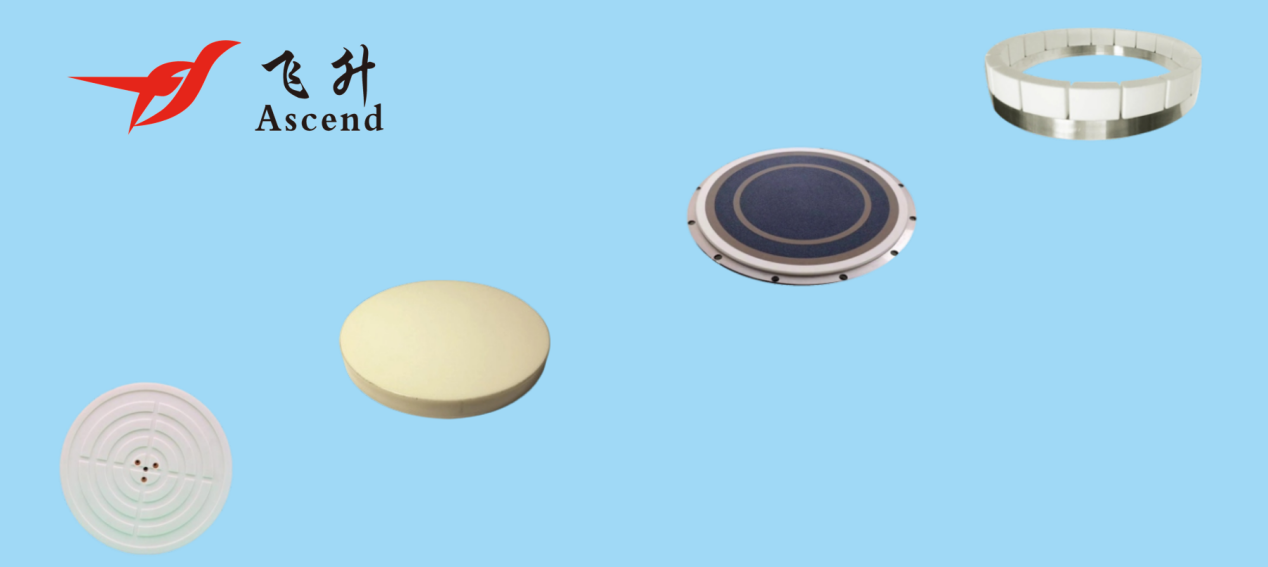

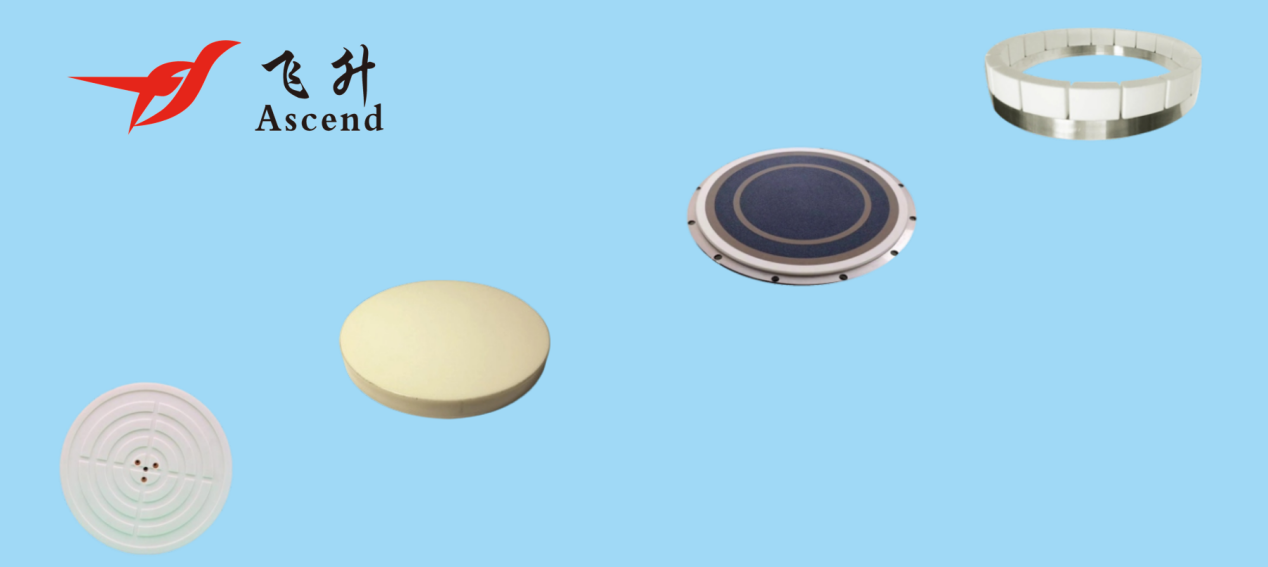

Applications of Precision Ceramics in Semi-Conductor Sector

https://www.ascendtechs.com/applications-of-precision-ceramics-in-semi-conductor-sector.html

With outstanding physical and chemical properties, precision ceramics, especially advanced structural ceramics, have become one of crucial roles in semi-conductor manufacturing industrial chain. Applications of precision ceramics cover multiple stages like chips manufacturing, testing, packaging, etc. Semi-conductor manufacturing processes have specific requirements on materials’ purity, heat resistance, wear resistance, corrosion resistance and electrical insulation. And properties of precision ceramics exactly satisfy these needs perfectly, promising powerful support for semi-conductor manufacturing industrial.

Applications of precision ceramic parts have occupied multiple critical processes in semi-conductor equipment manufacturing. In wafer manufacturing, wafer polishers have to depend on polishing heads and carrier plates made from alumina (Al2O3) ceramics or SiC ceramics. High hardness and wear resistance of these ceramics ensure the flatness and uniformity in the wafer polishing, preventing wafer precision from impacted by component wear. And in the following heat treatment, equipment like epitaxial furnace, oxidation furnace, diffusion furnace, etc adopt silicon nitride (Si3N4) ceramics or aluminum nitride (AlN) ceramics to make furnace tubes and other carriers. High heat resistance and resistance to high-temperature gas corrosion of these ceramics enable their stable performances in process environments with temperatures of several hundred degrees Celsius or even higher, ensuring wafer heat treatment quality.

Due to extreme requirements on accuracy, lithography machine apply components, such as precision guide rails and locating pins, mainly made from zirconia (ZrO2) ceramics or silicon nitride (Si3N4) ceramics. Low coefficient of thermal (CTE) and high rigidity of these ceramics can reduce thermal deformation and vibration during equipment operation, ensuring the precise transfer of lithography patterns. And in wafer etching, the materials of reaction chamber liners and gad nozzles in etchers usually adopt SiC ceramics or alumina (Al2O3) ceramics. Such ceramics can resist the erosion of corrosive gases during the etching process, preventing the components from corroding and contaminating the reaction chamber, and maintaining the stability of etching process.

The deposition chamber trays and target supports of the deposition equipment often use aluminum nitride (AlN) ceramics or SiC ceramics. These ceramics are capable of withstanding the high-temperature environment during the deposition process. And they also have outstanding electrical insulation properties, which can prevent electrical interference from affecting the quality of film deposition. While ion beam guide tubes and target stages of ion implantation machines always use SiC ceramics, whose high hardness and resistance to high-energy ion impact promise accuracy of ion implantation direction and reduce component wear.

In the testing and packaging stage, probe holders of probe stations and mold inserts of packaging machines usually apply alumina (Al2O3) ceramics or zirconia (ZrO2) ceramics, whose properties of insulation and wear resistance ensure electrical stability during testing and extend the service life of packaging molds at the same time.

Nowadays, types of ceramics mainly adopted in semi-conductor sector include alumina (Al2O3), silicon nitride (Si3N4), aluminum nitride (AlN), SiC, etc. Different types of ceramics with their properties meet the requirements of various semi-conductor equipment and processes.

Guangzhou Ascend Precision Machinery Co., Ltd is dedicated to providing customers with high-quality precision ceramic products and services. Guangzhou Ascend has its own factory covering an area of 7,000m2, and is equipped with 80 production and testing devices, ensuring the quality of precision ceramic products from production to quality inspection. Based on attention to customer needs, Guangzhou Ascend undertakes custom processing services for precision ceramics. Whether it is the carrier plate of a wafer polishing machine, the liner of an etching machine’s reaction chamber, or other specialized ceramic components for semi-conductor equipment, they can all be custom-made according to the drawings provided by the customer. If you have custom processing needs for precision ceramics, please feel free to contact us at any time. We will provide you with professional solutions and services.

https://www.ascendtechs.com/applications-of-precision-ceramics-in-semi-conductor-sector.html

Guangzhou Ascend Precision Machinery Co.,Ltd.